So I was busy lapping my H100 and 2600K and I glanced over at my setup and my MSI GTX460 Cyclone (stock OC 725MHz) caught my eye...

Long ago I replaced the stock cyclone HSF with an Artic Cooling Accelero XTREME Plus. At the time I was mildly curious if I should lap the HSF surface as well as the IHS of the GPU, but I didn't do it then.

Not so anymore. I pulled off the Accelero Extreme HSF thinking I would figure out a way to lap that GTX460 IHS now.

Notice those aluminum heatspreaders sitting on the vrm's on 3 sides of the GPU...those are adhesive glued onto the vrm's and they aren't coming off so that I could get in that area to lap the IHS directly.

So then I started thinking about the next alternative...why not just pop the lid off the GTX460 altogether? I could lap it freehand and then reattach it to the GPU, or just go bare-silicon if I can figure out a way to avoid cracking the exposed chip.

To pop the lid off the GPU, it was surprising easy, I used a standard razor blade:

I forcefully inserted it into one corner of the IHS interface with the GPU's PCB, then I tapped on it with a very small carpenter's hammer until it penetrated the corner by about 3/16". (sorry no pics with the razor stuck in the IHS, the lid came off before I could stage it for a photo)

I did one corner, then the other corner (same side, since I did not have a good angle of entry for the other two corners owing to the vrm heatsinks)...and "pop" it just came off in a matter of seconds with some slight prying of the blade.

I'll be honest, I had my eyes closed at the time because I didn't have my safety glasses on (I'm actually quite paranoid about that) and I did not want the blade itself to shatter and throw shards into my eyes.

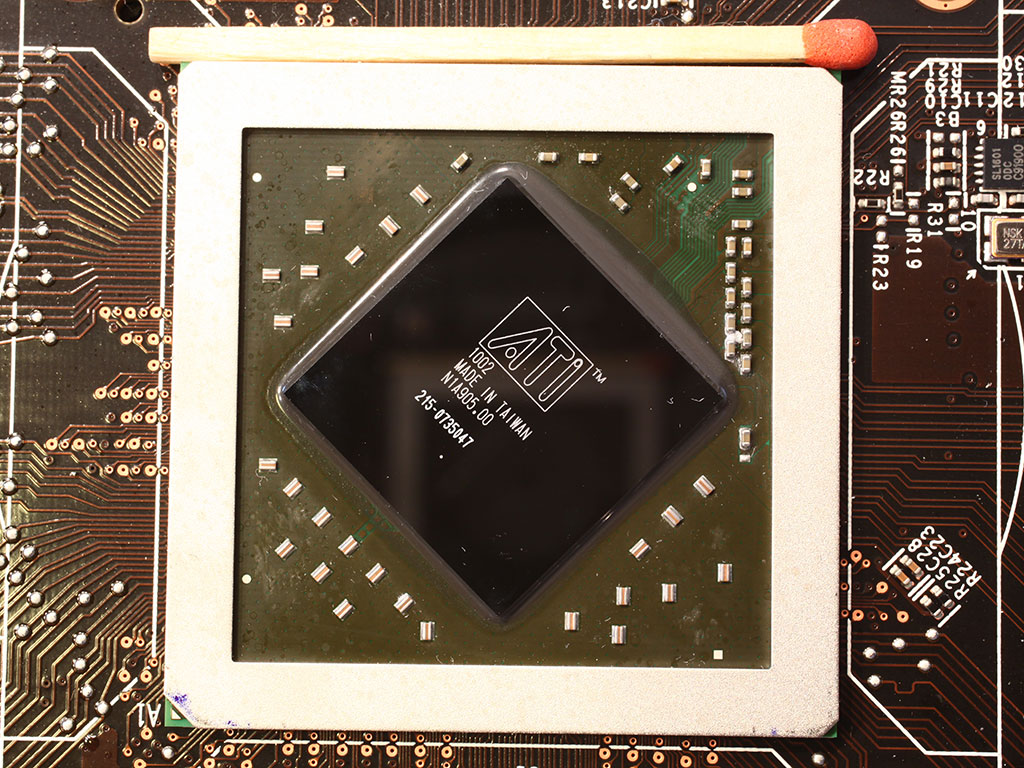

Nevertheless it popped off and I was left with:

As luck would have it, I managed to avoid shearing off the capacitors that surround the perimeter of the GPU chip itself when I was tapping the blade into the interface below the IHS.

That gray stuff you see on top of the GPU chip and on the inside surface of the IHS is just regular TIM, its not soldered to the IHS at all.

Cleaned up with some 91% IPA and standard kitchen paper towels:

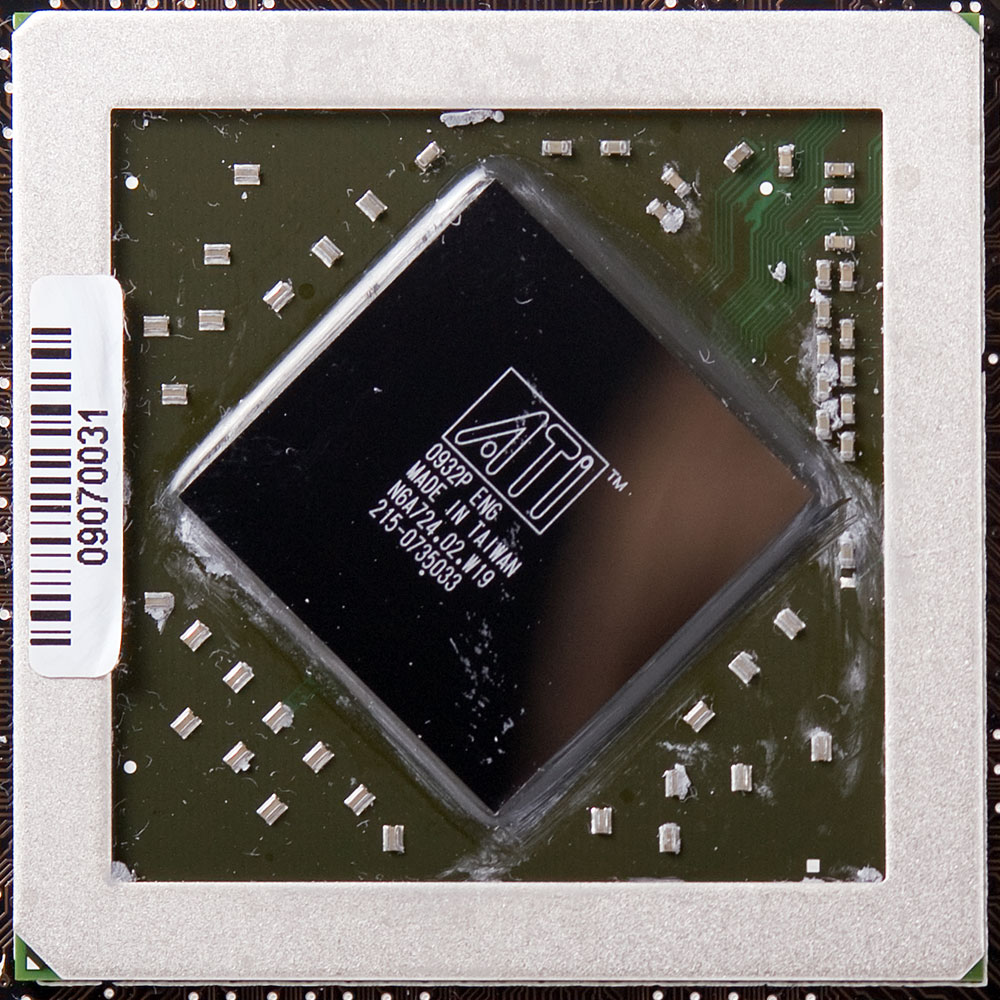

I was rather surprised how porous and rough the internal surface of the IHS is, no wonder they had to add liberal amounts of TIM to that interface:

Now that the lid is off I am posed with a new challenge, the Accelero Extreme HSF has stand-offs built into the mounting bracket. The stand-offs of course are designed to accommodate the relatively thick IHS cap of the GTX460.

So my choices are: (1) lap the IHS and reseat it back onto the GPU chip, or (2) cut down the HSF stand-offs and attempt to place the HSF's copper surface directly onto the GPU silicon.

Option (2) is clearly the highest-risk highest-reward option. I'd really like to not crack the chip and kill the GPU. On the other hand I'm immensely curious to see just how much lower the temps will be with that ghastly IHS block NOT standing in the way of the heat transfer to the HSF.

So what does the VC&G community have to say? Anyone here have experience with delidded chips? (I missed all that fun back with delidding AMD chips before they started soldering them on permanent-like) Got any advice on how much or how little pressure I can apply to the chip before it goes poof?

edit: results are in, see post 38, 10C decrease in temps with OCCT.

Long ago I replaced the stock cyclone HSF with an Artic Cooling Accelero XTREME Plus. At the time I was mildly curious if I should lap the HSF surface as well as the IHS of the GPU, but I didn't do it then.

Not so anymore. I pulled off the Accelero Extreme HSF thinking I would figure out a way to lap that GTX460 IHS now.

Notice those aluminum heatspreaders sitting on the vrm's on 3 sides of the GPU...those are adhesive glued onto the vrm's and they aren't coming off so that I could get in that area to lap the IHS directly.

So then I started thinking about the next alternative...why not just pop the lid off the GTX460 altogether? I could lap it freehand and then reattach it to the GPU, or just go bare-silicon if I can figure out a way to avoid cracking the exposed chip.

To pop the lid off the GPU, it was surprising easy, I used a standard razor blade:

I forcefully inserted it into one corner of the IHS interface with the GPU's PCB, then I tapped on it with a very small carpenter's hammer until it penetrated the corner by about 3/16". (sorry no pics with the razor stuck in the IHS, the lid came off before I could stage it for a photo)

I did one corner, then the other corner (same side, since I did not have a good angle of entry for the other two corners owing to the vrm heatsinks)...and "pop" it just came off in a matter of seconds with some slight prying of the blade.

I'll be honest, I had my eyes closed at the time because I didn't have my safety glasses on (I'm actually quite paranoid about that) and I did not want the blade itself to shatter and throw shards into my eyes.

Nevertheless it popped off and I was left with:

As luck would have it, I managed to avoid shearing off the capacitors that surround the perimeter of the GPU chip itself when I was tapping the blade into the interface below the IHS.

That gray stuff you see on top of the GPU chip and on the inside surface of the IHS is just regular TIM, its not soldered to the IHS at all.

Cleaned up with some 91% IPA and standard kitchen paper towels:

I was rather surprised how porous and rough the internal surface of the IHS is, no wonder they had to add liberal amounts of TIM to that interface:

Now that the lid is off I am posed with a new challenge, the Accelero Extreme HSF has stand-offs built into the mounting bracket. The stand-offs of course are designed to accommodate the relatively thick IHS cap of the GTX460.

So my choices are: (1) lap the IHS and reseat it back onto the GPU chip, or (2) cut down the HSF stand-offs and attempt to place the HSF's copper surface directly onto the GPU silicon.

Option (2) is clearly the highest-risk highest-reward option. I'd really like to not crack the chip and kill the GPU. On the other hand I'm immensely curious to see just how much lower the temps will be with that ghastly IHS block NOT standing in the way of the heat transfer to the HSF.

So what does the VC&G community have to say? Anyone here have experience with delidded chips? (I missed all that fun back with delidding AMD chips before they started soldering them on permanent-like) Got any advice on how much or how little pressure I can apply to the chip before it goes poof?

edit: results are in, see post 38, 10C decrease in temps with OCCT.

Last edited: