Noctua NH-D14 vs Corsair H100 for 2600K OC'ing? Update: Went with both!

Page 4 - Seeking answers? Join the AnandTech community: where nearly half-a-million members share solutions and discuss the latest tech.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RussianSensation

Elite Member

- Sep 5, 2003

- 19,458

- 765

- 126

Bump, any updates?

I've got some more pics of the lapping progress on the H100. My DDR3 is in for rma right now so I can't boot the system to do jack. Hoping to get my ram back in another week.

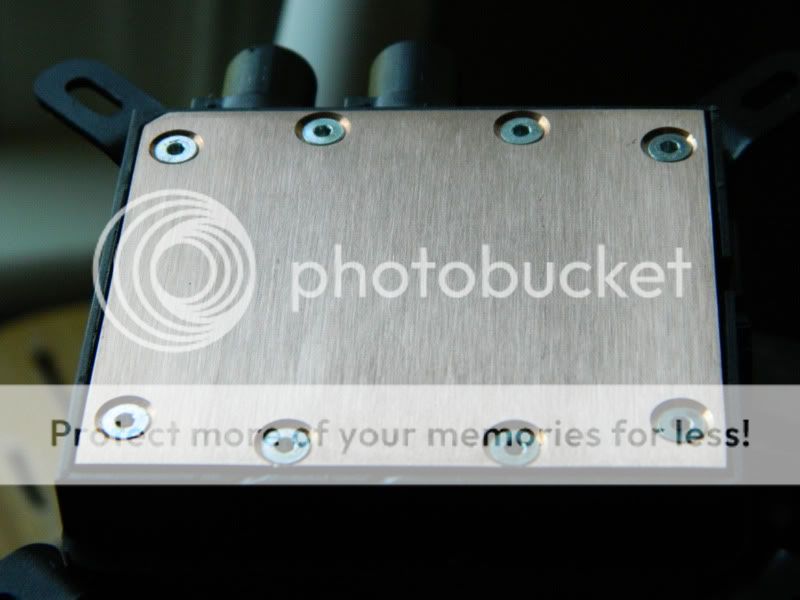

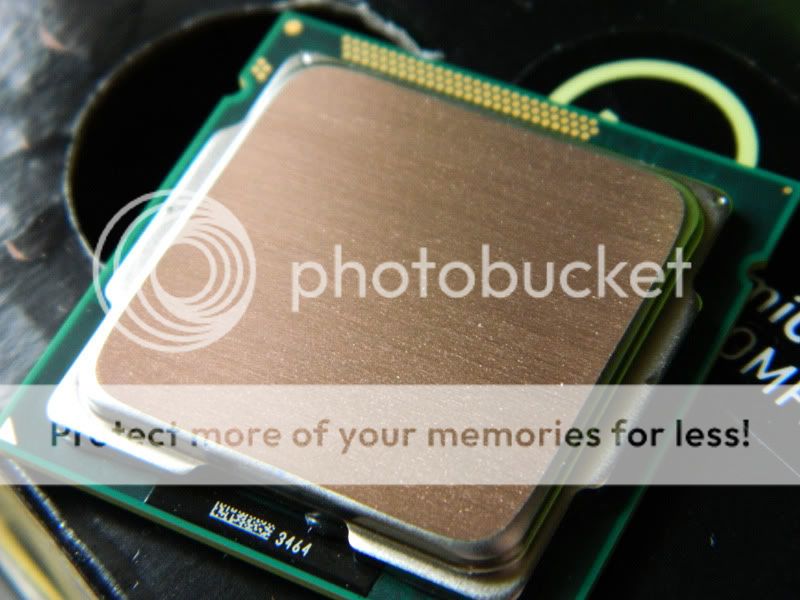

This was my H100, after I cleaned off the stock factory applied TIM:

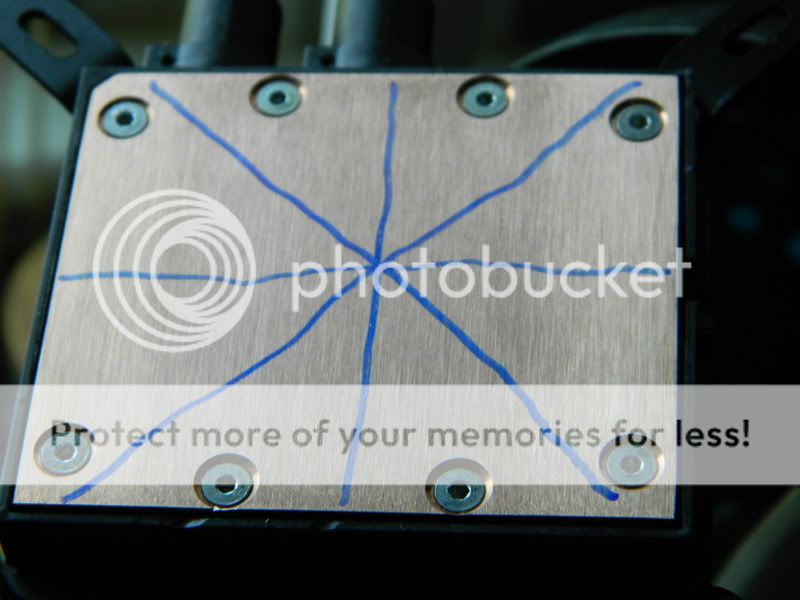

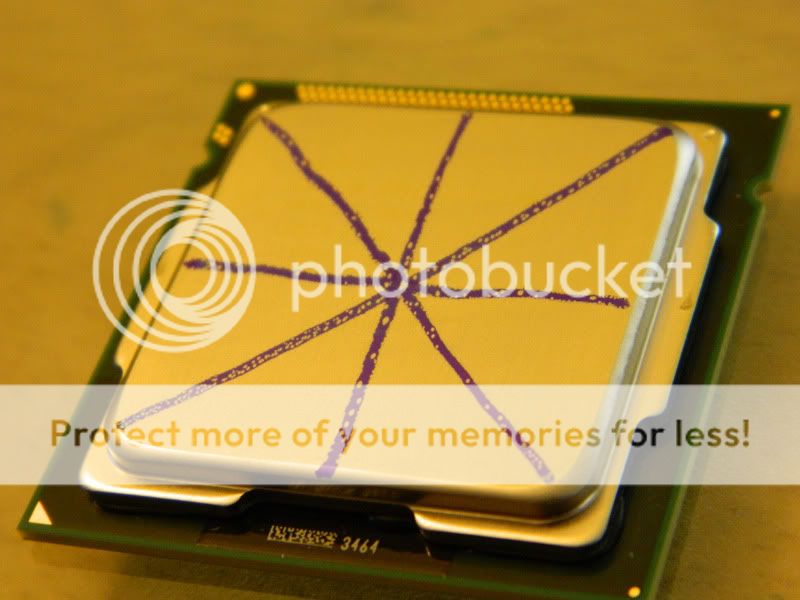

I drew in my hatch pattern with a sharpie pen:

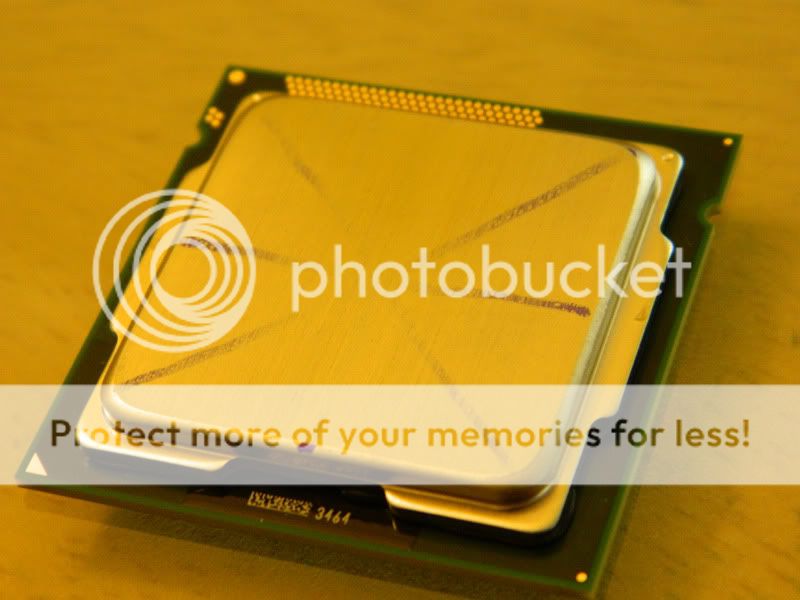

Did a few passes on 220 grit to see just how level (or unlevel) the stock surface is:

Ugh, that is not good at all. D:

Warped in a concave fashion, the left and right sides are high, the middle is a trough. Not what you want to see in your $110 cooler

More passes on 220 grit:

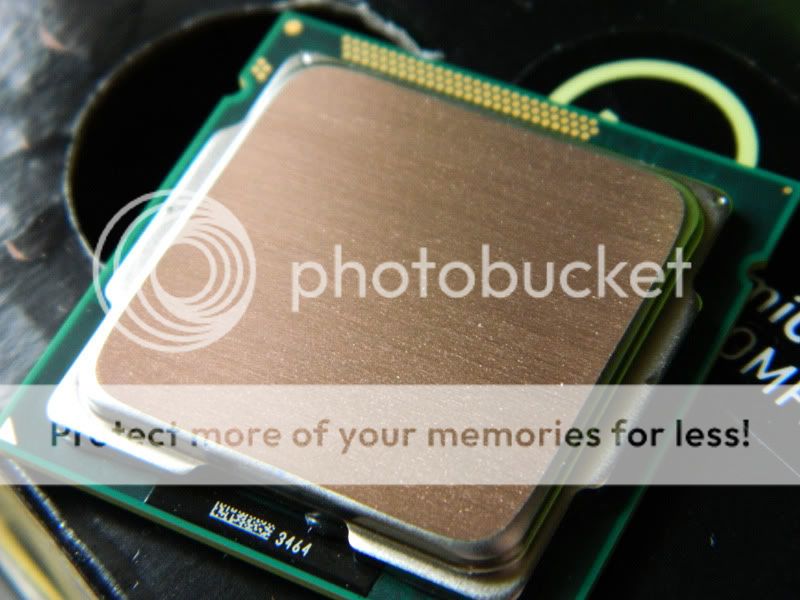

And finally got to the bottom of the trough in the center:

And finally it is flat:

...anecdotal comments -> I've lapped a fair amount of CPU's and HSF's in my time, this H100 was by far the most twisted, warped, pain in the freaking ass surface I have ever tried to lap.

Sure it looked flat, but this thing must have been taken out of a heat treatment furnace and dropped straight into a bucket of ice water to be as concave and contorted as it was.

I'm not finished lapping it yet and I've already got easily more than 3-4x the time invested in sanding this thing that my other HSF's and CPU's have taken.

That said, it has me extremely curious to see how much better my H100 temps are going to be now that this sucker is actually flattened.

Could be

dawp

Lifer

- Jul 2, 2005

- 11,345

- 2,705

- 136

How do you keep your abrasive flat? Do you use some sort of sanding block?

I used a piece of glass and wet/dry sandpaper.

How do you keep your abrasive flat? Do you use some sort of sanding block?

I have plate glass tops on my desks. I remove one and place onto a wooden table which is quite sturdy.

For the H100 itself, since I can't readily disassemble it, I built a sort of "shuttle" contraption out of a shoe-box, a towel, some rubber bands, and a cardboard skid to go underneath (not all shown in the photo below) so that the radiator housing would easily slide around on the glass top while I polished it:

I uploaded a short video to youtube showing the "shuttle" in action.

http://www.youtube.com/watch?v=r6Nq86ZdbdA

The camera is actually mounted on a tripod but you wouldn't know it from how shaky the video is...that's actually the "auto image stabilizer" trying to track the H100 sitting on top of the shoe-box rather than keeping the background wall, lamp, table fixed in space technology, you got to love it!

technology, you got to love it!

http://www.youtube.com/watch?v=r6Nq86ZdbdA

The camera is actually mounted on a tripod but you wouldn't know it from how shaky the video is...that's actually the "auto image stabilizer" trying to track the H100 sitting on top of the shoe-box rather than keeping the background wall, lamp, table fixed in space

I just bought a Thermaltake Frio OCK... the base was like that...anecdotal comments -> I've lapped a fair amount of CPU's and HSF's in my time, this H100 was by far the most twisted, warped, pain in the freaking ass surface I have ever tried to lap.

It took me two sessions to even get to remotely fix it. It's now pretty flat and shiny, but the edges are still "roundy" (I don't know how to describe it - but in your pic atop your text I quoted, it is something like that... the very edge is "lower" than the flat surface, at least on that one side of yours - my sides are all like that, I hate it, I must have sanded it in a rage due to how warped the POS was). Not sure I can live with it, but the damned thing was so warped. After I first sanded it with the rough grit, I said to myself "oh crap, I'd need a metal file, not a sandpaper".

And that's why the Amish people reject modern technologytechnology, you got to love it!

I just bought a Thermaltake Frio OCK... the base was like that

It took me two sessions to even get to remotely fix it. It's now pretty flat and shiny, but the edges are still "roundy" (I don't know how to describe it - but in your pic atop your text I quoted, it is something like that... the very edge is "lower" than the flat surface, at least on that one side of yours - my sides are all like that, I hate it, I must have sanded it in a rage due to how warped the POS was). Not sure I can live with it, but the damned thing was so warped. After I first sanded it with the rough grit, I said to myself "oh crap, I'd need a metal file, not a sandpaper".

And that's why the Amish people reject modern technologyThat shaking despite a tripod is clearly the work of the devil.

The word you are looking for is bevel.

The bevel forms because the sandpaper itself will stretch under the applied shear force of the item you are lapping. And while momentarily stretched, the paper rolls up in front of the leading edge of the HSF or IHS and applies a force that is no longer normal to the surface.

From my background, bachelors in MSE, I had to prepare metallographic samples for photomicrographic inspection (looking at grain structure, etc). In order to avoid the formation of bevels around the perimeter of the metal specimens under study you must mount them in a sample holder (bakelite or other thermosetting polymer) which then planarizes along with the metal surface.

We don't have the luxury of being able to mount our HSF's and IHS's in a thermosetting polymer so as to avoid beveling during the lapping process.

For us, the only practical way to avoid beveling is to drastically reduce the rate of sanding, avoid wet-sanding (it tends to make the sandpaper stretch more), combined with frquently pulling the paper tight.

It is only a superficial concern though, aesthestics. The functional impact to heat transfer from having a bevel is going to be non-existent for the HSF (there is no contact at the edge) and quite minimal for the CPU.

You could get an estimate for the effect though, its simply an areal reduction for the heat flux, so a perimeter area versus the residual area of the IHS. I'd guestimate the effect is 1-2% tops.

Right, bevel, exactly what the Photoshop effect that looks exactly like that is called  Now I am so shamed I did not think to use that word and instead called it "roundy".

Now I am so shamed I did not think to use that word and instead called it "roundy".

Anyhoo, the real problem is the bevelled edges are too "wide" (at least, upon my disapproving ocular, followed by the disapproving "tsk, tsk, tsk" along with the disapproving head-shaking, then followed by "curse you, thermaltake and my rage-induced sanding!" along with some righteous fist-shaking). Yours is appreciably thinner. That's why I think I may have been using too much force on it and ended up sanding the edges too much after each 90-degree rotation. It's just that the damn surface worked up a rage in me

Oh well, I already spent two sessions repairing the goddam warped surface, I'll finish the job this weekend and minimize the goddam rounding - err, "bevelling".

Anyhoo, the real problem is the bevelled edges are too "wide" (at least, upon my disapproving ocular, followed by the disapproving "tsk, tsk, tsk" along with the disapproving head-shaking, then followed by "curse you, thermaltake and my rage-induced sanding!" along with some righteous fist-shaking). Yours is appreciably thinner. That's why I think I may have been using too much force on it and ended up sanding the edges too much after each 90-degree rotation. It's just that the damn surface worked up a rage in me

Oh well, I already spent two sessions repairing the goddam warped surface, I'll finish the job this weekend and minimize the goddam rounding - err, "bevelling".

I uploaded a short video to youtube showing the "shuttle" in action.

http://www.youtube.com/watch?v=r6Nq86ZdbdA

The camera is actually mounted on a tripod but you wouldn't know it from how shaky the video is...that's actually the "auto image stabilizer" trying to track the H100 sitting on top of the shoe-box rather than keeping the background wall, lamp, table fixed in spacetechnology, you got to love it!

That is an awesome setup.

Do you use anything to wet the paper, or do you sand dry? I restored a turntable dust cover a couple of years back, and found that Formula 409 worked nicely for this.

That is an awesome setup.

Do you use anything to wet the paper, or do you sand dry? I restored a turntable dust cover a couple of years back, and found that Formula 409 worked nicely for this.

Thanks!

Depending on what I am sanding, I do both wet and dry.

For the CPU I strictly do dry-sanding only. You do not want to risk having the copper-loaded slurry making its way into the CPU pocket that is underneath the IHS itself (there is a hole on one side of the package).

For the HSF, and only for the coarser grits (220/400/800), I do wet sanding because the paper loads up rather quick.

When I get to the finer grits (1000/2000/3000) I do dry sanding because I actually want to take advantage of the dynamic nature of the effective grit as the paper becomes loaded. The more you load the 1000 grit, the more it begins to effectively become a 1500 or 2000 grit paper near the end of the sanding.

Makes the transitions between successive grit paper much more seamless IMO.

Digital Savior

Member

- Sep 17, 2011

- 26

- 0

- 0

Thanks for the tip, will come in useful when I get the backbone to sand a good CPU :thumbsup:For the CPU I strictly do dry-sanding only. You do not want to risk having the copper-loaded slurry making its way into the CPU pocket that is underneath the IHS itself (there is a hole on one side of the package).

JEDIYoda

Lifer

- Jul 13, 2005

- 33,981

- 3,318

- 126

Hello there, Idontcare -- we've been poking in these forum doors since '07 if I remember. . . .

I have the Noctua D-14. I could've easily sprung for the Megahalem. Just off the top of my head, the water-cooling options may give you about 10C to 15C advantage. I took a look at the H100, and was impressed. I must've looked at one of those preassembled H80's or something even less formidable. And I haven't attempted to build a WC rig yet. That being said, I did see some statistical results comparing some water-cooling systems to the air options, and planning on at least a possibility of replacing the Noctua with a decent WC kit, I somehow came to the conclusion about that 10C to 15C advantage.

Somebody else, please correct me if I'm wrong about that.

I've just spent a few days putting an i7-2600K through its paces. Techs at ASUS cite their own figures that something like 40% of their 2600K's will OC to 4.6/4.7 Ghz; another 40% might go to 4.8/4.9, and the remainder will OC to 5.0 Ghz. While that may be "on air," it just seems to me you have two choices:

-- Stay within the thermal and voltage specs (although there apparently isn't a reliable, official voltage spec -- but the Sandy is 32nm silicon like the Nehalem, so infer it from that)

-- Cool the heck out of it and overvolt the CPU until you get to 5.0 or beyond

With the air coolers, you can stay within the thermal spec and still OC to the Nehalem voltage spec -- more . . . or less . . . . You might be able to reach 4.7 Ghz and only peak out the temperature at 4 to 5C above the throttling threshold -- that is, I mean by throttling according to the TM1 "Adaptive Thermal Monitoring." People say [people say . . ] that you can run these processors beyond 80C, and the TJunction temperature is around 98C.

Some people are pushing these things well above the thermal spec of 72.6C on air. It's thin silicon, so you can choose to add a little more risk with each successive increment of voltage and heat.

So it all depends on whether the 10 to 15C actually makes it possible to get stability at a lower voltage. I'm just not so sure that it does. You may stay well within the 72.6 C limit or any looser limit you care to define. After that, it's just a matter of the voltage.

With my system, I was able to get to 4.73 with the peak "Maximum stress" IntelBurnTest temperature at around 76C. That was with the Noctua. Also keep in mind that I have a biased thermal sensor under the cap that probably contributes to reporting a temperature that is 5C or so in excess of the true temperature. So it MAY be that my 4.73 Ghz was really giving a temperature of about 72 to 73C.

And the fact is -- if you're cautious about voltage, if that's the game you're playing with yourself (because that's my game, too) -- the Noctua or competing heatpipe cooler would be adequate to get to "that point" -- 1.37V or so. At that point -- maybe a little sooner -- your temperatures will be pushing toward 80C. Maybe, with the bias in my own sensors and a "guesstimate" about what they really are, 75C. Maybe a tad better.

I've had exchanges with others here -- and seen forum posts elsewhere -- with people reporting 4.8 Ghz and temperatures in the low 80's. One Intel tech told an enthusiast: "Who SAID you can run these chips above 80C degrees?!"

That's what the Intel guy said, and others here may tell you something different.

hey there my friend!! I am still lurking and collecting heatsinks...lol.....

Those were the days.....

JEDIYoda

Lifer

- Jul 13, 2005

- 33,981

- 3,318

- 126

Thanks!

Depending on what I am sanding, I do both wet and dry.

For the CPU I strictly do dry-sanding only. You do not want to risk having the copper-loaded slurry making its way into the CPU pocket that is underneath the IHS itself (there is a hole on one side of the package).

For the HSF, and only for the coarser grits (220/400/800), I do wet sanding because the paper loads up rather quick.

When I get to the finer grits (1000/2000/3000) I do dry sanding because I actually want to take advantage of the dynamic nature of the effective grit as the paper becomes loaded. The more you load the 1000 grit, the more it begins to effectively become a 1500 or 2000 grit paper near the end of the sanding.

Makes the transitions between successive grit paper much more seamless IMO.

I never had a need to do the sanding thing! To each there own...

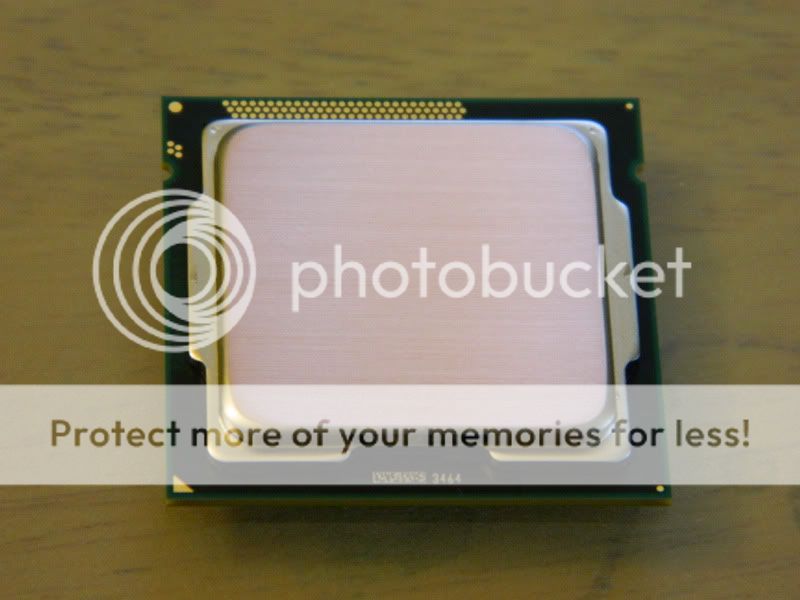

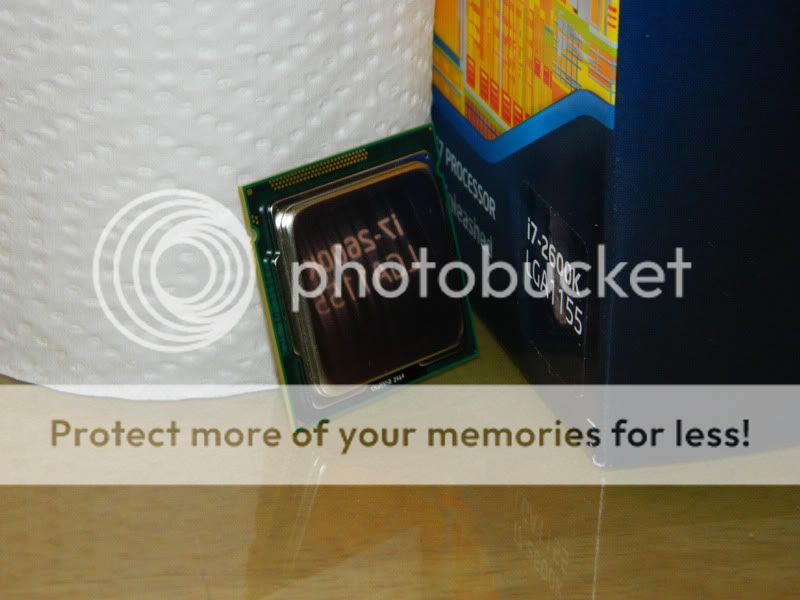

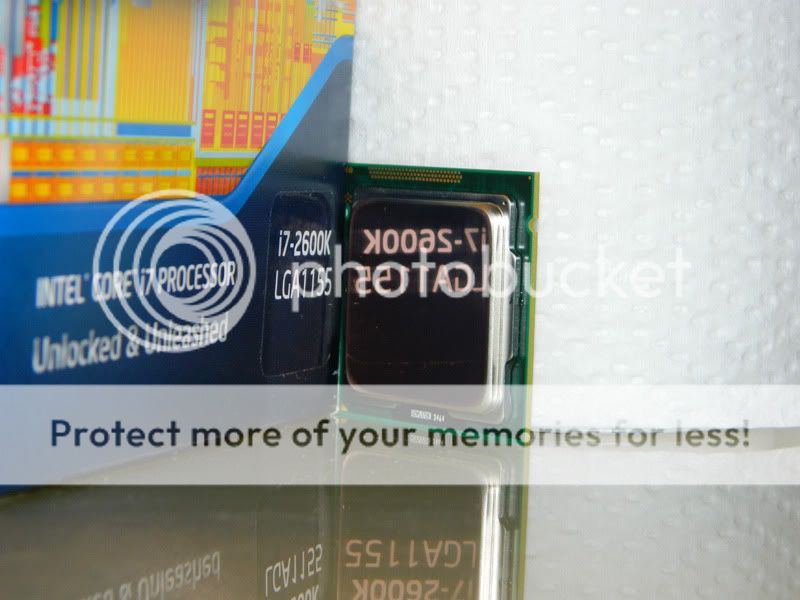

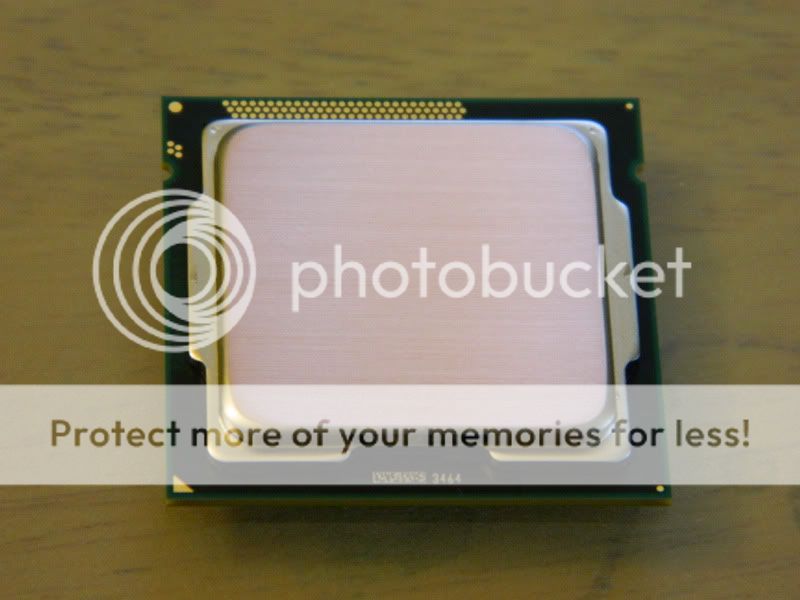

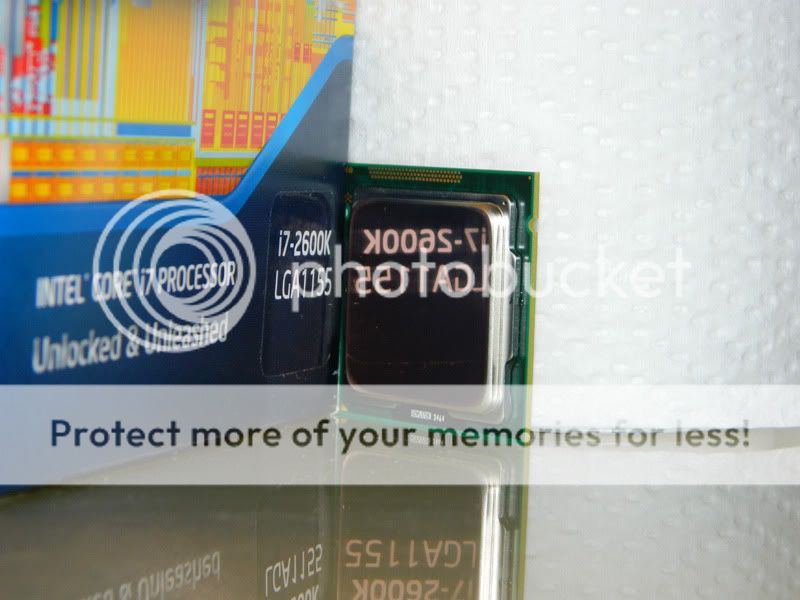

Lapping my 2600K went rather easily, unlike the H100, the 2600K chip was rather flat to begin with.

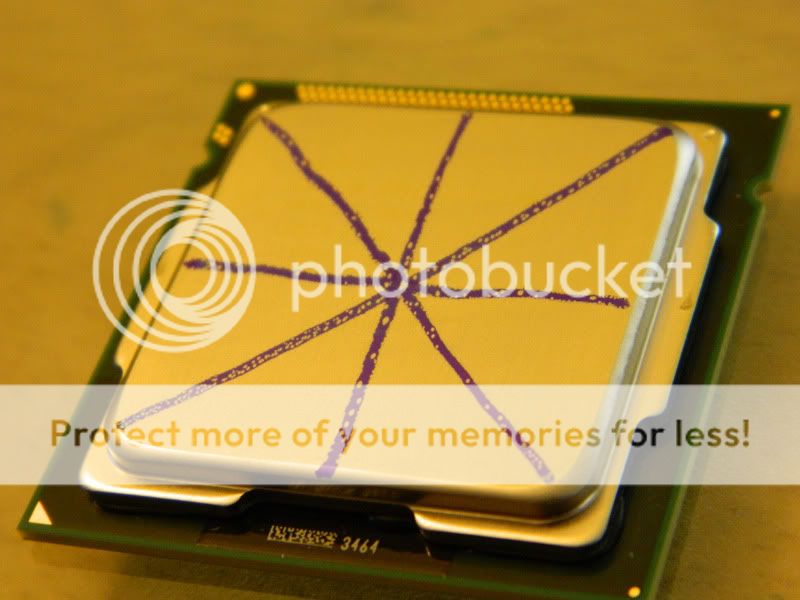

Hatch marks added:

After a few passes on 220grit, the IHS was clearly Convex (buldges outward in the middle, which was the first part of the IHS to get sanded down):

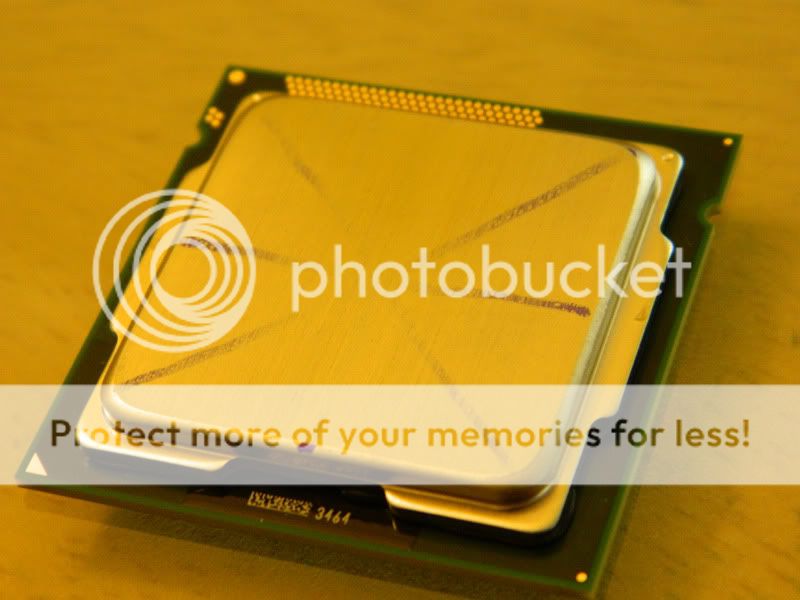

After 220 grit:

After 400 grit:

After 1000 grit:

After 2000 grit:

After 3000 grit:

Hatch marks added:

After a few passes on 220grit, the IHS was clearly Convex (buldges outward in the middle, which was the first part of the IHS to get sanded down):

After 220 grit:

After 400 grit:

After 1000 grit:

After 2000 grit:

After 3000 grit:

- Sep 28, 2005

- 20,846

- 3,190

- 126

NOOOOOOOOOOOOOO

IDC why did u lap that H#O.

:\

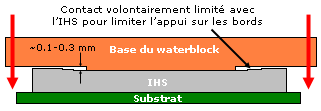

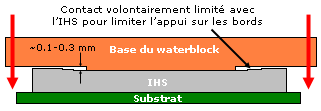

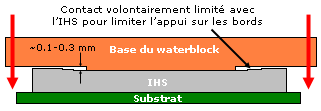

OK guys.... there has been a phase shift away from flat blocks for a while now.

We learned that when u apply pressure with a step, you get a better mount.

What does a Step mean?

Its a point in the center which forces the IHS on the CPU to warp, and hence get a better contact over the die location.

A better explanation from my pal Vapor.

This is also why orientation is important in mounting a waterblock, and its vital to do more then 1 mount if your going after consistency.

This applies only in waterblocks... heat sinks as far as i know dont see a big advantage in having a step.

In waterblocks this step is more called a BOW effect.

Now if u think my spanking of you is over... why did u blow all that money in sinks when u could of just gone water, and seen temps which would be illegal to post in that comparison?

At the very least IDC, your gpu's would of seen an OMGWTFBBQ reduction in half the current temps it has.

IDC why did u lap that H#O.

:\

OK guys.... there has been a phase shift away from flat blocks for a while now.

We learned that when u apply pressure with a step, you get a better mount.

What does a Step mean?

Its a point in the center which forces the IHS on the CPU to warp, and hence get a better contact over the die location.

A better explanation from my pal Vapor.

Here's what I'm thinking in pictures....

Here's what we've had for years, not so great...

Then the bow came, and it was pretty darn good (almost too good in this pic, oh well, these were done quickly):

This assuming the bow is created because mounting pressure is along the top edges, and will happen to the entire base uniformly (or nearly). Nikh's idea to put the pressure back in the middle is awesome, but until we can mount with pressure down the middle, there will always be a bow (theory).

This is also why orientation is important in mounting a waterblock, and its vital to do more then 1 mount if your going after consistency.

This applies only in waterblocks... heat sinks as far as i know dont see a big advantage in having a step.

In waterblocks this step is more called a BOW effect.

Now if u think my spanking of you is over... why did u blow all that money in sinks when u could of just gone water, and seen temps which would be illegal to post in that comparison?

At the very least IDC, your gpu's would of seen an OMGWTFBBQ reduction in half the current temps it has.

Last edited:

lehtv

Elite Member

- Dec 8, 2010

- 11,900

- 74

- 91

Now if u think my spanking of you is over... why did u blow all that money in sinks when u could of just gone water, and seen temps which would be illegal to post in that comparison?

At the very least IDC, your gpu's would of seen an OMGWTFBBQ reduction in half the current temps it has.

I thought he's doing it for sake of comparison, and he's putting the other cooler into a HTPC

- Sep 28, 2005

- 20,846

- 3,190

- 126

I thought he's doing it for sake of comparison, and he's putting the other cooler into a HTPC

lololz...

he is..

but IDC is a nut in my book.

He is one of the very few who thought he was too good for water and hence skipped it entire and went on vapo phase instead.

Im trying to bring him to water.

Guys water has been super Dumb'd down in the past 5 yrs with people actively working with the vendors.

I have worked hard with koolance in feedback and help to have them bring out products which make OUR life's a lot easier.

Bitspower has heard all of us whine and complain about trying to get something to fit or work, and has suplimented us with a gignormous amount of fittings.

The self contained kits... dont get me wrong.. i love them only when your CPU clearance height is of concern.

But the one thing i cringe about is when a new person buys a self contained without doing any research on water because its "self contained" and expects to escape all the fundimental services required with ANY water product.

Also the user needs to realize, there is 1 more thing that can go wrong in a self contained water pump.

And air sink to some degree can run passive.

A water block Cant... the pump dies, the system will over heat.

The same can be said about the fan on the radiator.

If that dies... you are Screwed and your cpu will undergo thermal shutdown very soon.

But if u ever do encounter a thermal shutdown... dont freak out...

Find out why its shutting down.

If it is your cpu overheating.. the next time u try to boot up, bios will post:

CPU Fan failed... CPU is Overheating... or just CPU is Overheating.

<---guilty of not plugging in my pumps so yes ive seen those messages frequently.

NOOOOOOOOOOOOOO

IDC why did u lap that H#O.

:\

OK guys.... there has been a phase shift away from flat blocks for a while now.

We learned that when u apply pressure with a step, you get a better mount.

What does a Step mean?

Its a point in the center which forces the IHS on the CPU to warp, and hence get a better contact over the die location.

A better explanation from my pal Vapor.

This is also why orientation is important in mounting a waterblock, and its vital to do more then 1 mount if your going after consistency.

This applies only in waterblocks... heat sinks as far as i know dont see a big advantage in having a step.

In waterblocks this step is more called a BOW effect.

Now if u think my spanking of you is over... why did u blow all that money in sinks when u could of just gone water, and seen temps which would be illegal to post in that comparison?

At the very least IDC, your gpu's would of seen an OMGWTFBBQ reduction in half the current temps it has.

You'll note above in post #78 that I showed my H100 was significantly concave, not convex as needed to accomplish the effect you are referencing above.

- Sep 28, 2005

- 20,846

- 3,190

- 126

You'll note above in post #78 that I showed my H100 was significantly concave, not convex as needed to accomplish the effect you are referencing above.

lost then why does it show this here?

so you were bowing inside instead of outside?

Because scratch marks show its in the middle which leads me to think it was a bow.

But if ur saying your plate was in the inside.... man.... that is bad.. and yes u need to lap it so you can get the edges out smooth and get a more firm mount.

james1701

Golden Member

- Sep 14, 2007

- 1,873

- 59

- 91

NOOOOOOOOOOOOOO

One question, how to you get the center to bow down on the cpu and the corners up, when most blocks screw down from the outside corners and nothing in the middle to push down on it. Is that a saddle of some sorts over the block that pushes down when you screw it in?

I do think I am just about sold on going full blown water. I seen even Newegg is selling block and several things, except no res units.

Last edited:

TRENDING THREADS

-

Discussion Intel current and future Lakes & Rapids thread

- Started by TheF34RChannel

- Replies: 23K

-

Discussion Zen 5 Speculation (EPYC Turin and Strix Point/Granite Ridge - Ryzen 9000)

- Started by DisEnchantment

- Replies: 10K

-

-

Discussion Speculation: Zen 4 (EPYC 4 "Genoa", Ryzen 7000, etc.)

- Started by Vattila

- Replies: 13K

-

Discussion Intel Meteor, Arrow, Lunar & Panther Lakes Discussion Threads

- Started by Tigerick

- Replies: 7K

AnandTech is part of Future plc, an international media group and leading digital publisher. Visit our corporate site.

© Future Publishing Limited Quay House, The Ambury, Bath BA1 1UA. All rights reserved. England and Wales company registration number 2008885.