- Feb 14, 2005

- 10,341

- 678

- 126

https://wccftech.com/intel-9th-gen-core-cpus-specs-confirmed-core-i9-9900k-8-core-soldered-ihs/

Result, no more delidding!

Result, no more delidding!

I know it's old. I waited to see what someone else posted. When I saw nothing I posted a link.Old news mate, looks legit though.

My bet is you'll be surprised.My bet is really not that much.

Lets hope so. After all these years of people griping about TIM, will be interesting to see how much difference solder actually makes. My bet is really not that much.

Wow, the solder melts when the CPU is stressed. This is news to almost everyone. Guess I've jumped realities.They moved away from solder not because it was cheaper, which is the soap box myth most people tout.

It was because as the waffer got thinner, and the node process smaller, the chip became more fragile.

They noticed the metal solder had a higher instance of damaging the die from the constant phase change stress (going from liquid state to solid ... on and off on a PC), and hence changed to paste.

Although it came at a cost of performance, to intel's eyes, the performance prices was enough merit over the longevity.

This is why they changed to paste.

And now i will see a lot of people start ranting because they can no longer delid the cpu, and run the die naked.

They moved away from solder not because it was cheaper, which is the soap box myth most people tout.

It was because as the waffer got thinner, and the node process smaller, the chip became more fragile.

They noticed the metal solder had a higher instance of damaging the die from the constant phase change stress (going from liquid state to solid ... on and off on a PC), and hence changed to paste.

Although it came at a cost of performance, to intel's eyes, the performance prices was enough merit over the longevity.

This is why they changed to paste.

And now i will see a lot of people start ranting because they can no longer delid the cpu, and run the die naked.

....

This site explains it in more detail then me...

Maybe links and picture should of been given with all the intel bashing this forum has lately...

https://overclocking.guide/the-truth-about-cpu-soldering/

So yeah, after the many thermal cycles, or so eventually it leads to micro cracks.

My honest take on it...

Solder is nice as it did improve thermal performance.

Lets be realistic here, the Thermal Conductivity for metal is in a factor of at least 10x greater then that of any oil or paste..

But to a non overclocker, i dont think that thermal conductivity is important.

Infact to most non overclocker, which tends to be either basic consumer machines, or office machines, i think longivity and more robust engineering is probably preferred.

To an overclocker tho, a moderate one at the least, that thermal conductivity can spell anywhere near 15-20% headroom.

So, i honestly feel, all "K"'s should of been soldered. A overclocker is not looking to keep the chip long term, and would rather want that thermal performance.

However putting back solder on the cpu to me is honestly mixed as we got easy methods of deliding a cpu. There are kits now to make it easy, and the razor with silicon wedges like how i did my old Opty's back in the days are no longer needed.

If i was going to overclock the chip to hell, i would most likely delid it, skip putting the IHS back on completely, slap a flat waterblock on it with a direct die kit like these:

Because the IHS is to me another thermal barrier which i would want to get rid of.

And a Soldered CPU would make it more difficult to do so....

But *shrug* that is just me....

"der8auer" said:Intense thermal cycling will damage the solder preform significantly. Tensile stress inside the solder preform will lead to voids (Figure 10).

Micro cracks occur after about 200 to 300 thermal cycles. A thermal cycle is performed by going from -55 °C to 125 °C while each temperature is hold for 15 minutes.

Well to fair, they might get to do it once.If you read the article it says these cracks are caused by,

Now I don't know about you but I sure as hell have never heard of anybody doing that to a CPU.

Basically Intel has disagreed with everyone who said soldering was not possible with finfet chips,so why are people now bashing Intel for using it.

Intel hasn't said anything to that effect - only that using solder increased the RMA rates.

I wish people would start reading a bit,from the link above that explains it all.Well apparently Intel thinks solder now does not have that problem,as they are soldering their K series chips,which consume the most power of the consumer line,which by extension will cause more issues with thermal cycling if its true. AMD apparently does not agree as all their Ryzen CPUs,and the Threadripper CPUs are all soldered and their cheapo CPUs don't have it. AMD has far less leeway for increased RMA rates than Intel due to their financial situation anyway - they should be using thermal compound as their margins are lower.

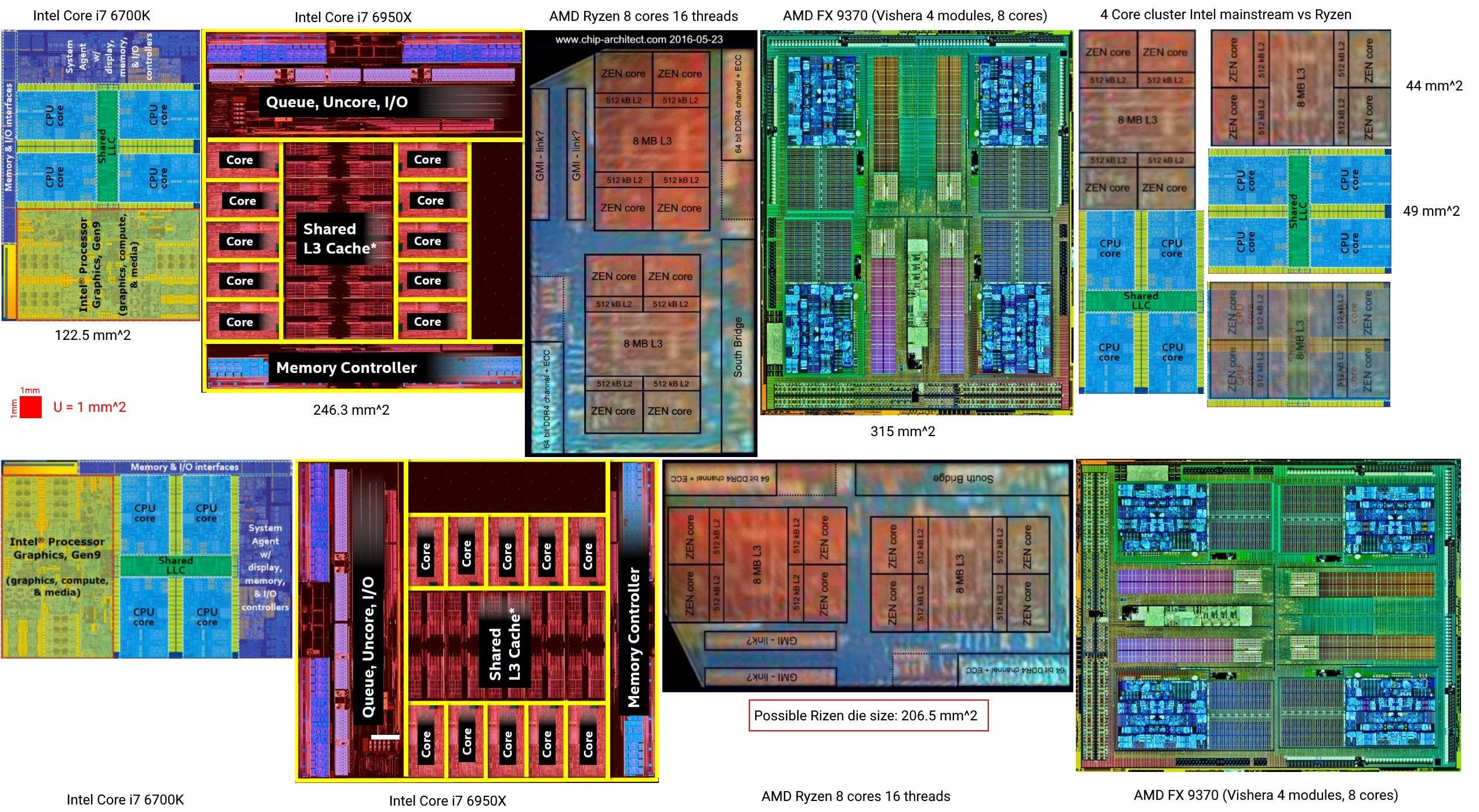

On small dies (what you call cheapo for AMD) neither intel or amd uses solder for this reason.Void and micro crack occurrence is mainly affected by the solder area – thus the DIE size. Small DIE size (below 130 mm²) e. g. Skylake will facilitate the void occurence significantly. However, CPUs with a medium to large DIE size (above 270 mm²) e. g. Haswell-E show no significant increase of micro cracking during thermal cycling (Figure 12).

I wish people would start reading a bit,from the link above that explains it all.

Intense thermal cycling will damage the solder preform significantly. Tensile stress inside the solder preform will lead to voids (Figure 10).

Micro cracks occur after about 200 to 300 thermal cycles. A thermal cycle is performed by going from -55 °C to 125 °C while each temperature is hold for 15 minutes.

Void and micro crack occurrence is mainly affected by the solder area – thus the DIE size. Small DIE size (below 130 mm²) e. g. Skylake will facilitate the void occurence significantly. However, CPUs with a medium to large DIE size (above 270 mm²) e. g. Haswell-E show no significant increase of micro cracking during thermal cycling (Figure 12).

At the end of the day it's all about cost just as it's always been. Intel has been using paste for it's CPUs for a long time, much longer than Ivy bridge. For example, a Core 2 Duo E7200 uses paste but a Core 2 Duo E8200 is soldered. It obviously wasn't something technical that caused Intel to use paste for the E7200, it was price as they're almost the same exact chips.

Well apparently Intel thinks solder now does not have that problem,as they are soldering their K series chips

No one is bashing Intel for using solder. I don't see where you got that idea. In my case, I'm bashing all the posters who spent the last year ridiculing those of us, who were bashing Intel for NOT using solder on their high end CPUs, They claimed all sort of technical reasons why solder is bad, and now have gone silent.Well apparently Intel thinks solder now does not have that problem,as they are soldering their K series chips,which consume the most power of the consumer line,which by extension will cause more issues with thermal cycling if its true. AMD apparently does not agree as all their Ryzen CPUs,and the Threadripper CPUs are all soldered and their cheapo CPUs don't have it. AMD has far less leeway for increased RMA rates than Intel due to their financial situation anyway - they should be using thermal compound as their margins are lower.

Also,people are literally bashing Intel for using solder now and now trying to spread fear that the CPUs are more likely to fail. So are people saying we should buy a Core i7 8700K instead of a Core i7 9700K,since the solder "might" cause more problems?? People worry too much - I hate to think how many of you would have felt about pencil mods and old Athlons which would catch fire if the cooler failed!