who is wrenching today?

Page 31 - Seeking answers? Join the AnandTech community: where nearly half-a-million members share solutions and discuss the latest tech.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Nov 21, 2001

- 22,014

- 4,783

- 146

Thanks Fuzzy, looking good.My condolences about your puppy Skyking.

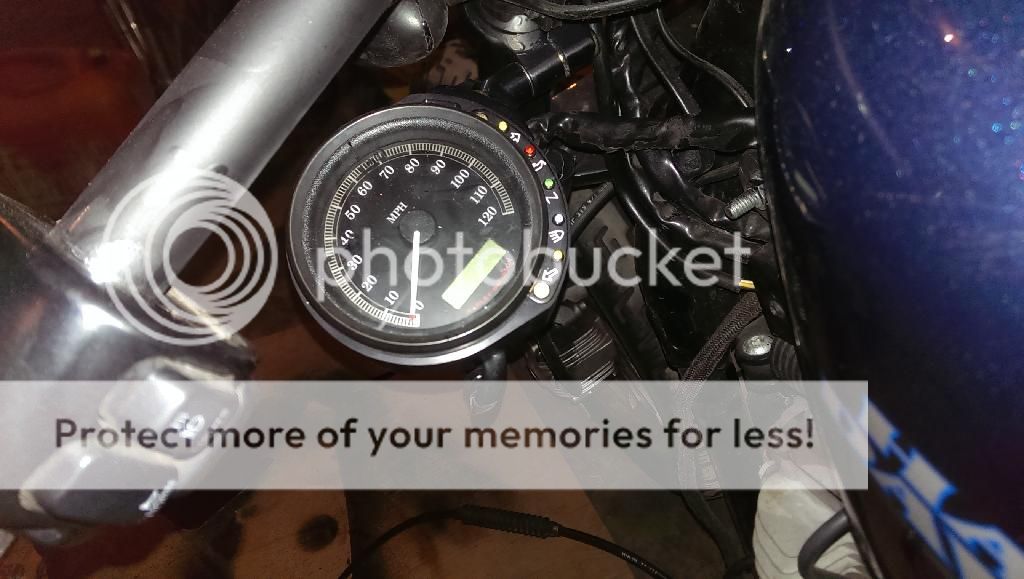

As requested.

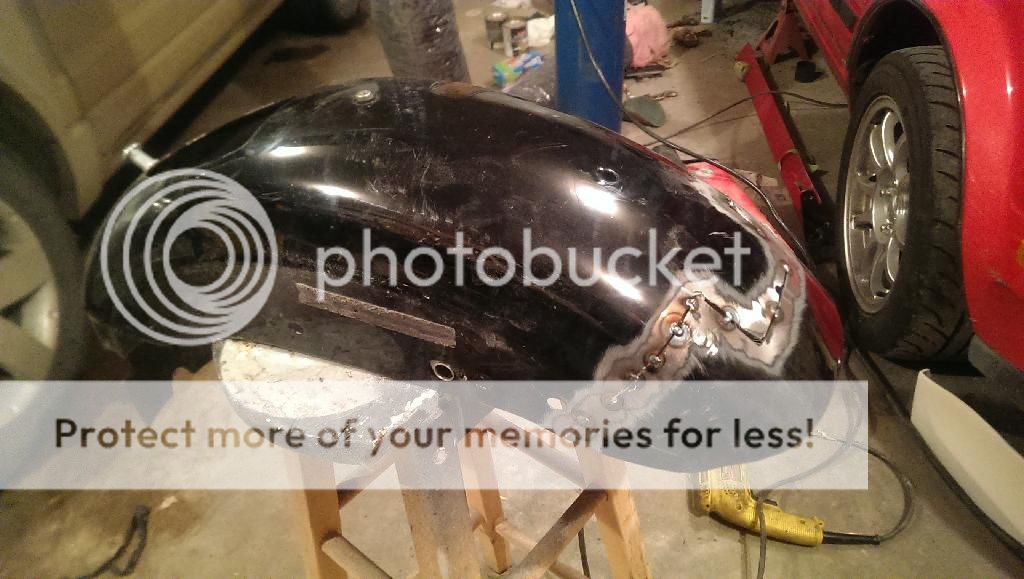

This weekend I cut up the rear fender.

shortylickens

No Lifer

- Jul 15, 2003

- 82,854

- 17,365

- 136

FuzzyDunlop

Diamond Member

- Jan 30, 2008

- 3,261

- 12

- 81

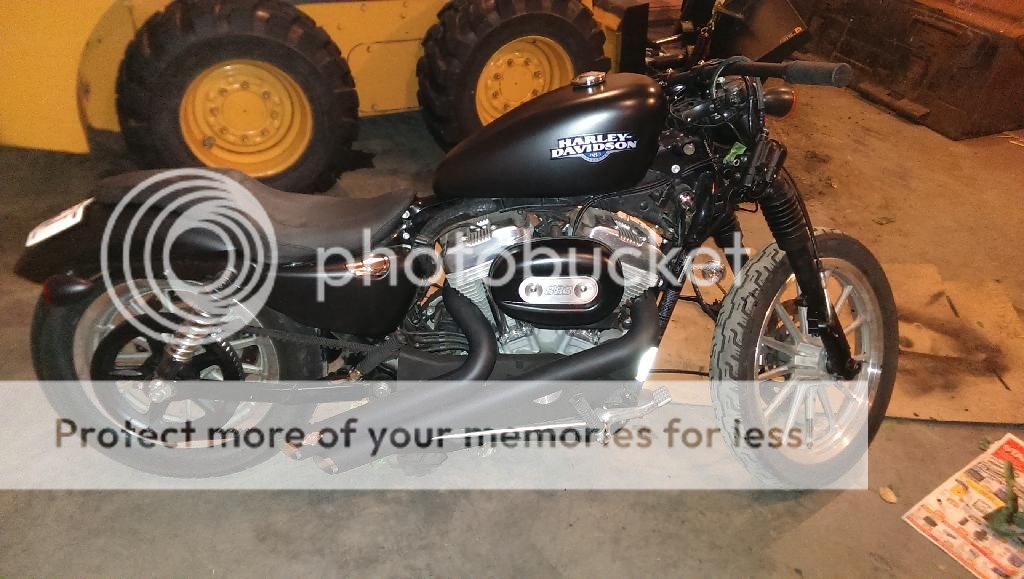

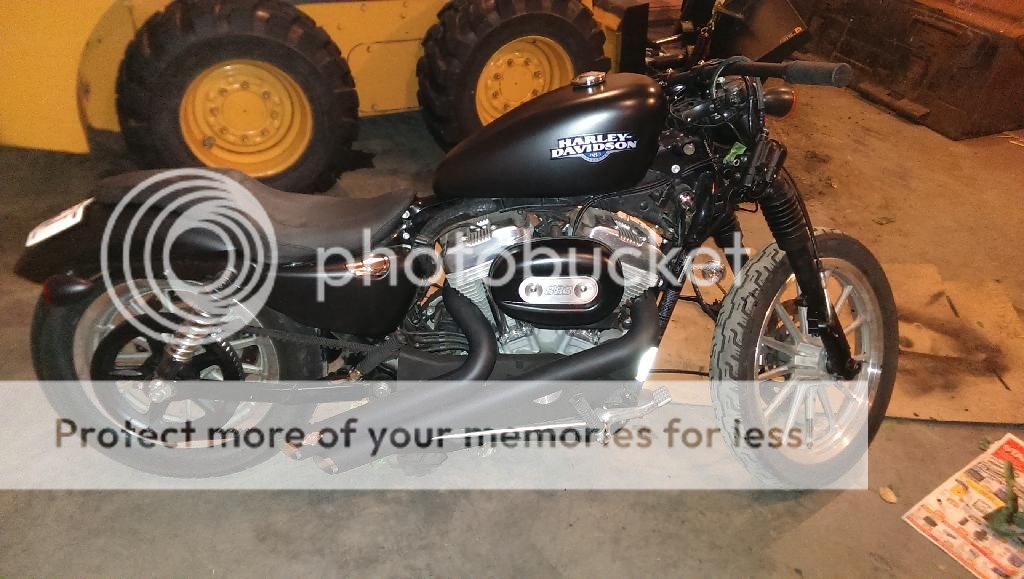

Painted my tank today.

Just need to reinstall the front controls (broke a piece) and Im set for summer. May it come quickly!

Just need to reinstall the front controls (broke a piece) and Im set for summer. May it come quickly!

deerslayer

Lifer

- Jan 15, 2001

- 10,153

- 0

- 76

Painted my tank today.

Just need to reinstall the front controls (broke a piece) and Im set for summer. May it come quickly!

How do you like those pipes? V&H sideshots?

FuzzyDunlop

Diamond Member

- Jan 30, 2008

- 3,261

- 12

- 81

ya, V&H. They sound mean. More throaty than the stock. My bike was loud already, these dont seem that much louder, but Ive only heard them in the garage.

They were tricky to install (have to find just the right angles) but I like them. My brother wants to get the same for his Dyna.

They were tricky to install (have to find just the right angles) but I like them. My brother wants to get the same for his Dyna.

deerslayer

Lifer

- Jan 15, 2001

- 10,153

- 0

- 76

ya, V&H. They sound mean. More throaty than the stock. My bike was loud already, these dont seem that much louder, but Ive only heard them in the garage.

They were tricky to install (have to find just the right angles) but I like them. My brother wants to get the same for his Dyna.

I've been eyeing the staggered short shots for my softail, but I just don't want to spend the money on the pipes and tuner. The bike came with rush slip ons. They don't sound too bad, and I can pooch it out of the neighborhood without waking up my kids. I borrowed my brother in law's v-rod with cfr exhaust (no baffles) for a couple weeks one summer. I had to roll that about a block away before I fired it up. He finally got nailed for loud exhaust and had to put baffles in it.

Busy weekend for me last weekend. Installed Coilovers, FIGS Rear lower control arms, FIGS rear toe arms, FIGS Lower front control arm bushing on my ISF and then Sunday built a new exhaust on my 1988 Toyota Soarer and swapped wheels around on it. Twas a good weekend!

skipsneeky2

Diamond Member

- May 21, 2011

- 5,035

- 1

- 71

Did some wrenching yesterday on my 88 taurus which someone gave me for free.Dropped in a 160f thermostat so my car in this cold weather could run warmer and for the moment stop a cold idle stalling problem most likely caused by the IAC or Map sensor.Runs rich but the stalling has disappeared for the moment lol.

olds

Elite Member

- Mar 3, 2000

- 50,056

- 714

- 126

Installed Pop & Lock on the tailgate of my Tacoma yesterday. The shell locks but with a little force you could open the tailgate. Now the tailgate locks.

Also bought a racheting cargo bar and mounted a piece of plywood to it to put in the bed as a divider. Now items can't slide up to the front of the bed. No more climbing in for small items.

Also bought a racheting cargo bar and mounted a piece of plywood to it to put in the bed as a divider. Now items can't slide up to the front of the bed. No more climbing in for small items.

Last edited:

GoodRevrnd

Diamond Member

- Dec 27, 2001

- 6,803

- 581

- 126

Well, what should have been an afternoon project turned into a week long ordeal to install my short shifter and tranny mounts. Got sent the wrong shifter, was sold shift carrier arm bearings that shouldn't even be used on this car, and decided it would be a good idea to attempt replacing the shift carrier arm bushing w/ the exhaust and drive shaft still in. Not the best experience for my first solo car wrenching, but it is finally complete!

And now I just realized that I think I forgot to lock the shift arm carrier pin... fml.

And now I just realized that I think I forgot to lock the shift arm carrier pin... fml.

- Nov 21, 2001

- 22,014

- 4,783

- 146

I bought a friend of mine a truck today, an 88 Mooshibooshi Mighty Max. Total beater for 500 clams, starts stops turns, everything works.

On the way home I noticed a massive clunking from the right side with a steering wheel wiggle. The idler arm has rubber bushings and they are missing! $10.49 at Autozone

On the way home I noticed a massive clunking from the right side with a steering wheel wiggle. The idler arm has rubber bushings and they are missing! $10.49 at Autozone

I just found a coolant leak, so I had to put a new radiator and hoses in the 97 Civic today. On the street. At night. Ugh, I always forget how much it sucks to deal with underhood parts that haven't been touched since the car was new and are now baked on. At least it was a fairly straightforward operation once the hoses were off.

I have a searing hatred for whoever invented the three-tab spring clamp. Sure, if you have clean access to them they're not bad, but tucked away in the middle of the engine it's almost impossible to capture all three tabs with your pliers, cleanly squeeze them together, and then slide the whole assembly in the right direction without any of them slipping out.

I have a searing hatred for whoever invented the three-tab spring clamp. Sure, if you have clean access to them they're not bad, but tucked away in the middle of the engine it's almost impossible to capture all three tabs with your pliers, cleanly squeeze them together, and then slide the whole assembly in the right direction without any of them slipping out.

I just found a coolant leak, so I had to put a new radiator and hoses in the 97 Civic today. On the street. At night. Ugh, I always forget how much it sucks to deal with underhood parts that haven't been touched since the car was new and are now baked on. At least it was a fairly straightforward operation once the hoses were off.

I have a searing hatred for whoever invented the three-tab spring clamp. Sure, if you have clean access to them they're not bad, but tucked away in the middle of the engine it's almost impossible to capture all three tabs with your pliers, cleanly squeeze them together, and then slide the whole assembly in the right direction without any of them slipping out.

These are your greatest friend when dealing with hose clamps like those: http://www.amazon.com/OTC-4525-Cable...e+clamp+pliers

FuzzyDunlop

Diamond Member

- Jan 30, 2008

- 3,261

- 12

- 81

These are your greatest friend when dealing with hose clamps like those: http://www.amazon.com/OTC-4525-Cable...e+clamp+pliers

PuRCHaSiNG NoW!!!

T2urtle

Diamond Member

- Oct 18, 2004

- 3,432

- 3

- 81

These are your greatest friend when dealing with hose clamps like those: http://www.amazon.com/OTC-4525-Cable...e+clamp+pliers

Agreed.

Helps everywhere!!! I learned about this tool doing a engine swap, makes life so much easier.

TridenT

Lifer

- Sep 4, 2006

- 16,810

- 45

- 91

A lot of crap this for this late Friday to late Saturday. Car was stolen and my maintenance schedule was also about to climax when it was stolen. I was going to do this over many weekends instead of one. (Less stress, more time, etc.) Also an oil leak in my car got to the unacceptable point. I've realized now that it was the oil pan gasket, but I also needed a new valve cover gasket because I think the seals for the spark plugs were throwing just the tiniest amount of oil into them.

What I planned for today and tomorrow:

Oil pan gasket (http://www.youtube.com/watch?v=rVadCt-xJTY&hd=1 )

Valve cover gasket (Doesn't even need a video it's so damn simple)

Oil change with filter (Early)

ATF change (drain+fill) (On time to early)

Power steering fluid change (mega-drain, fill; http://www.youtube.com/watch?v=nWm5bTwl38w&hd=1 ) (Overdue)

Go to pick n pull and get a special bracket for the steering column and replace the one in my car. (Mine was damaged during theft of car and has made the steering column very difficult to impossible to adjust)

Remove trunk interior. (There's a smell that the thieves left on it... yay...)

If time, fit carpet better. (Not install, just get the fit down better; it was pretty bad when I left it) Carpet I got is medium beige. My interior is dark grey. (ACC is the worst in terms of photography of their carpets)

I live in Seattle. The garage I work in is down near PDX. This complicates things since I have a busy life.

I had to buy a new air gun today because I didn't realize what I was getting myself into. I broke the old one on replacing disk rotors and never replaced it. I thought I didn't need to do anything with the exhaust and then I got under the car and was like, "Weird. Somehow I forgot that the exhaust is totally blocking the oil pan. Nice... So how should I do this, Internet?" And even with a breaker bar I couldn't get the exhaust bolts to come loose. (I didn't give it my all because I knew if it broke then my hands would slam into something and get busted) So... off to Harbor Freight.

Bought this from Harbor Freight: http://www.harborfreight.com/air-to...-in-professional-air-impact-wrench-68424.html

Broke a 14mm chrome socket immediately with that on the exhaust coming off the exhaust manifold onto the rest of downpipe. That sucked since it was the only 14mm socket in the entire garage. (There are no metric sockets in the garage; just a few SAE) And, it was 8:00PM by that time. Luckily, Harbor Freight closes at 9:00. Rushed over there and got some supposedly impact sockets (They cost like 1.5-3 times as much as the other impact sockets that are chromes just painted black;scammy,much?) and some replacement chrome sockets that are color-coordinated. (Deep sockets for the impacts; couldn't decide between deep or standard, didn't want to pay for both, honestly. Also, the color chromes feel cheap and are 12 point. (Hate, but no choice) ) Also bought a chrome adapter set. (1/2" to 3/8", 3/8" to 1/4", etc.) They didn't have a true impact adapter set from what I could tell. Their extenders were also just chromes painted black.

EDIT: After realizing they're all chromes. (In a sense. Chrome-vanadium vs chrome-moly) I have to rephrase. They were painting CVs black. It didn't look like the painted black CVs were very much different from the other sockets. (Maybe thicker in construction) From my reading now about what a good impact socket is, CM seems to be the choice since it is less prone to exploding and taking out your eye.

Pic doesn't show it, but it is in the middle of it all. I didn't do as the video did for the oil pan because I didn't want to risk it with my downpipe to cat connection. I felt like the bolts might be so rusty that they'll just never go back on. Similarly, felt like that about any possible gaskets that would be there. Raised the exhaust on that joint (the rusty one...) with the jack and then wiggled off the middle rubber hanger for the full exhaust and moved the exhaust over a bit to give me clearance for the oil pan. There is a lot of flexibility at that joint btw. The downpipe hangs down quite a bit. So, there's quite a bit of movement possible with that connection. Surprisingly so, for me. But I don't know too much about exhausts.

Seemed to work out. I have the oil pan off and I took the valve cover off (Valve cover is too damn easy after that oil pan). Cleaned the oil pan as much as I could, but I might run it down with a pressure washer/hose tomorrow. (My environmental side hates getting any oil out there, but I need that fucker to be clean for the seal; also need to easily track whether or not I have oil leaks; maybe I am doing some harm now but more good in the end?) Same for valve cover.

Any suggestions on brushes to be using for cleaning these, btw? I assume I shouldn't use a steel wire brush.

In the end, I'll probably get the ATF, oil change, oil pan gasket, and the valve cover gasket done by the end of tomorrow. (7-8PM) I'll probably head back to Seattle after that. I would have really liked to gotten a lot more done, but having to take a couple trips to HF and then run into some issues... well, it's taken up a lot more time than I guessed. I did remove the trunk interior actually. It was remarkably easy. It'll get a nice cleaning but I won't put it back in until next weekend. (Doesn't matter, entire car interior is gutted)

What I planned for today and tomorrow:

Oil pan gasket (http://www.youtube.com/watch?v=rVadCt-xJTY&hd=1 )

Valve cover gasket (Doesn't even need a video it's so damn simple)

Oil change with filter (Early)

ATF change (drain+fill) (On time to early)

Power steering fluid change (mega-drain, fill; http://www.youtube.com/watch?v=nWm5bTwl38w&hd=1 ) (Overdue)

Go to pick n pull and get a special bracket for the steering column and replace the one in my car. (Mine was damaged during theft of car and has made the steering column very difficult to impossible to adjust)

Remove trunk interior. (There's a smell that the thieves left on it... yay...)

If time, fit carpet better. (Not install, just get the fit down better; it was pretty bad when I left it) Carpet I got is medium beige. My interior is dark grey. (ACC is the worst in terms of photography of their carpets)

I live in Seattle. The garage I work in is down near PDX. This complicates things since I have a busy life.

I had to buy a new air gun today because I didn't realize what I was getting myself into. I broke the old one on replacing disk rotors and never replaced it. I thought I didn't need to do anything with the exhaust and then I got under the car and was like, "Weird. Somehow I forgot that the exhaust is totally blocking the oil pan. Nice... So how should I do this, Internet?" And even with a breaker bar I couldn't get the exhaust bolts to come loose. (I didn't give it my all because I knew if it broke then my hands would slam into something and get busted) So... off to Harbor Freight.

Bought this from Harbor Freight: http://www.harborfreight.com/air-to...-in-professional-air-impact-wrench-68424.html

Broke a 14mm chrome socket immediately with that on the exhaust coming off the exhaust manifold onto the rest of downpipe. That sucked since it was the only 14mm socket in the entire garage. (There are no metric sockets in the garage; just a few SAE) And, it was 8:00PM by that time. Luckily, Harbor Freight closes at 9:00. Rushed over there and got some supposedly impact sockets (They cost like 1.5-3 times as much as the other impact sockets that are chromes just painted black;scammy,much?) and some replacement chrome sockets that are color-coordinated. (Deep sockets for the impacts; couldn't decide between deep or standard, didn't want to pay for both, honestly. Also, the color chromes feel cheap and are 12 point. (Hate, but no choice) ) Also bought a chrome adapter set. (1/2" to 3/8", 3/8" to 1/4", etc.) They didn't have a true impact adapter set from what I could tell. Their extenders were also just chromes painted black.

EDIT: After realizing they're all chromes. (In a sense. Chrome-vanadium vs chrome-moly) I have to rephrase. They were painting CVs black. It didn't look like the painted black CVs were very much different from the other sockets. (Maybe thicker in construction) From my reading now about what a good impact socket is, CM seems to be the choice since it is less prone to exploding and taking out your eye.

Pic doesn't show it, but it is in the middle of it all. I didn't do as the video did for the oil pan because I didn't want to risk it with my downpipe to cat connection. I felt like the bolts might be so rusty that they'll just never go back on. Similarly, felt like that about any possible gaskets that would be there. Raised the exhaust on that joint (the rusty one...) with the jack and then wiggled off the middle rubber hanger for the full exhaust and moved the exhaust over a bit to give me clearance for the oil pan. There is a lot of flexibility at that joint btw. The downpipe hangs down quite a bit. So, there's quite a bit of movement possible with that connection. Surprisingly so, for me. But I don't know too much about exhausts.

Seemed to work out. I have the oil pan off and I took the valve cover off (Valve cover is too damn easy after that oil pan). Cleaned the oil pan as much as I could, but I might run it down with a pressure washer/hose tomorrow. (My environmental side hates getting any oil out there, but I need that fucker to be clean for the seal; also need to easily track whether or not I have oil leaks; maybe I am doing some harm now but more good in the end?) Same for valve cover.

Any suggestions on brushes to be using for cleaning these, btw? I assume I shouldn't use a steel wire brush.

In the end, I'll probably get the ATF, oil change, oil pan gasket, and the valve cover gasket done by the end of tomorrow. (7-8PM) I'll probably head back to Seattle after that. I would have really liked to gotten a lot more done, but having to take a couple trips to HF and then run into some issues... well, it's taken up a lot more time than I guessed. I did remove the trunk interior actually. It was remarkably easy. It'll get a nice cleaning but I won't put it back in until next weekend. (Doesn't matter, entire car interior is gutted)

Last edited:

TridenT

Lifer

- Sep 4, 2006

- 16,810

- 45

- 91

The worst happened today. Was using a torque wrench for this, but nearing 10ft/lbs, it seemed like the stuff would never stop turning. At 80in/lbs, it would stop so easy. At 100, it still stopped. 120in/lb? Never stopped turning. And, apparently, looking at the factory service manual, I misread the factory service manual... ugh.  Valve cover bolts were supposed to be done to 7.2ft/lbs and the oil pan was supposed to be 8.7ft/lbs. I don't know why 10ft/lbs even came up in my mind, but apparently that's what stuck. Would explain a few things. I overtightened everything by a significant margin. Le-fuck.

Valve cover bolts were supposed to be done to 7.2ft/lbs and the oil pan was supposed to be 8.7ft/lbs. I don't know why 10ft/lbs even came up in my mind, but apparently that's what stuck. Would explain a few things. I overtightened everything by a significant margin. Le-fuck.

First, I broke a bolt off the engine block when tightening down the oil pan. That would take forever to fix. Poured sealant all over the area. It was at a critical spot too. (The nut is one of two that holds up a U shaped area of the oil span; frequent leaky area)

That was disheartening. Also, hondabond? It can go fuck itself. It is put in the WORST possible container and impossible to squeeze out from the tube into the little cone they give you. Don't even bother. Just grab it straight out the tube and spread with a finger or something. The stuff will break out of its thin metal containment otherwise.

Second to break off was one of the valve cover bolts. I just put the bolt back onto the cover and covered it with sealant. I didn't have time for this shit. And again, it happened with a torque wrench at <10ft/lbs. (This time I didn't break off a bolt coming out, I broke off the screw portion of the bolt (screwing into the head) in the hole. That means I need to either drill it out or get lucky and reverse it out with a hammer+chisel.(or an ez out)) The oil pan is worse and basically a nightmare. (Remove oil pan (takes forever); Sand down the bolt portion, perfectly drill a new hole where the bolt was, tap it, put a new bolt into it; pray it holds)

Here is the broken bits:

So, that's disheartening and I'm getting really frustrated with this car because I don't have the time. (School, job, I live 3+ hours away from the garage, and somuchmore)

First, I broke a bolt off the engine block when tightening down the oil pan. That would take forever to fix. Poured sealant all over the area. It was at a critical spot too. (The nut is one of two that holds up a U shaped area of the oil span; frequent leaky area)

That was disheartening. Also, hondabond? It can go fuck itself. It is put in the WORST possible container and impossible to squeeze out from the tube into the little cone they give you. Don't even bother. Just grab it straight out the tube and spread with a finger or something. The stuff will break out of its thin metal containment otherwise.

Second to break off was one of the valve cover bolts. I just put the bolt back onto the cover and covered it with sealant. I didn't have time for this shit. And again, it happened with a torque wrench at <10ft/lbs. (This time I didn't break off a bolt coming out, I broke off the screw portion of the bolt (screwing into the head) in the hole. That means I need to either drill it out or get lucky and reverse it out with a hammer+chisel.(or an ez out)) The oil pan is worse and basically a nightmare. (Remove oil pan (takes forever); Sand down the bolt portion, perfectly drill a new hole where the bolt was, tap it, put a new bolt into it; pray it holds)

Here is the broken bits:

So, that's disheartening and I'm getting really frustrated with this car because I don't have the time. (School, job, I live 3+ hours away from the garage, and somuchmore)

exdeath

Lifer

- Jan 29, 2004

- 13,679

- 10

- 81

Never use the upper or lower 20% of a clicker torque wrench , especially a cheap one. Particularly the low end since something requiring 100+ ft lbs is unlikey to strip or break. Best to have an assortment for various torque ranges so you are in the center.

Eg don't use a 150 ft lb or even 75 ft lb torque wrench to read 7 ft lbs.

Honestly for that low I'd use a 150 in lb wrench which places you at 84-96 in lb range.

Honestly though for stuff like valve covers don't even bother. Just squish down the seal, bottom out metal to metal, then one hand maybe halfway up the handle and give it a final tug. Those low torque value ratings for non critical fasteners are too easy to snap and strip things, esp without seriously expensive precise tools (eg not a $9 clicker)

If I have to torque something that low I prefer a beam style wrench.

Also use common sense and double check numbers. I caught a misprint error in the factory service manual working with JLee on his MR2 where they did something like swapped Nm with ftlb or used ftlb on something small that was clearly supposed to be inlbs.

Eg don't use a 150 ft lb or even 75 ft lb torque wrench to read 7 ft lbs.

Honestly for that low I'd use a 150 in lb wrench which places you at 84-96 in lb range.

Honestly though for stuff like valve covers don't even bother. Just squish down the seal, bottom out metal to metal, then one hand maybe halfway up the handle and give it a final tug. Those low torque value ratings for non critical fasteners are too easy to snap and strip things, esp without seriously expensive precise tools (eg not a $9 clicker)

If I have to torque something that low I prefer a beam style wrench.

Also use common sense and double check numbers. I caught a misprint error in the factory service manual working with JLee on his MR2 where they did something like swapped Nm with ftlb or used ftlb on something small that was clearly supposed to be inlbs.

Last edited:

TridenT

Lifer

- Sep 4, 2006

- 16,810

- 45

- 91

Never use the upper or lower 20% of a clicker torque wrench , especially a cheap one. Particularly the low end since something requiring 100+ ft lbs is unlikey to strip or break. Best to have an assortment for various torque ranges so you are in the center.

Eg don't use a 150 ft lb or even 75 ft lb torque wrench to read 7 ft lbs.

Honestly for that low I'd use a 150 in lb wrench which places you at 84-96 in lb range.

Honestly though for stuff like valve covers don't even bother. Just squish down the seal, bottom out metal to metal, then one hand maybe halfway up the handle and give it a final tug. Those low torque value ratings for non critical fasteners are too easy to snap and strip things, esp without seriously expensive precise tools (eg not a $9 clicker)

If I have to torque something that low I prefer a beam style wrench.

Also use common sense and double check numbers. I caught a misprint error in the factory service manual working with JLee on his MR2 where they did something like swapped Nm with ftlb or used ftlb on something small that was clearly supposed to be inlbs.

Yeah, it was a cheap $10 clicker. The range is 20-200in/lbs. I have a 5-80ft/lbs too. It was also cheap (Harbor freight), but it was actually calibrated (knew a guy who worked on Airforce jets and could do it) about 3-4 years ago. Still, not going to be that reliable.

Anyway, my common sense was peaking. I was going, "The fuck is going on here? This can't be legit...?" *snap* "NOOOOOO!"

And then up top, I was actually going around the bolts I had hand tightened down and was testing those and then the valve cover one broke once I did that on one of the bolts...

I'll be stopping by a junk yard for another appropriate valve cover bolt. Shouldn't be hard to find. Digging it out won't be that hard either. The hard part will be the oil pan and who knows when I'll do that. (Probably never unless it starts leaking...)

TRENDING THREADS

-

Discussion Intel current and future Lakes & Rapids thread

- Started by TheF34RChannel

- Replies: 23K

-

Discussion Zen 5 Speculation (EPYC Turin and Strix Point/Granite Ridge - Ryzen 9000)

- Started by DisEnchantment

- Replies: 10K

-

Discussion Speculation: Zen 4 (EPYC 4 "Genoa", Ryzen 7000, etc.)

- Started by Vattila

- Replies: 13K

-

Discussion Intel Meteor, Arrow, Lunar & Panther Lakes Discussion Threads

- Started by Tigerick

- Replies: 7K

-

AnandTech is part of Future plc, an international media group and leading digital publisher. Visit our corporate site.

© Future Publishing Limited Quay House, The Ambury, Bath BA1 1UA. All rights reserved. England and Wales company registration number 2008885.