EK has just announced a "naked ivy" mechanism for it's water blocks:

http://www.techpowerup.com/182088/E...-Lidded-Ivy-Bridge-CPU-Cooling-Solutions.html

http://www.techpowerup.com/182088/E...-Lidded-Ivy-Bridge-CPU-Cooling-Solutions.html

EK has just announced a "naked ivy" mechanism for it's water blocks:

http://www.techpowerup.com/182088/E...-Lidded-Ivy-Bridge-CPU-Cooling-Solutions.html

ended up delidding my processor and slapping prolimatech tim on the die and ihs.

temps dropped a massive 22C.

im gonna watch out for the pump-out effect. I've skimmed various threads and i've only seen as5 and nt-h1 suffer, so I'll have to see.

I'm happy with the temp drop. I'll go with CLU only if the temps start to get worse over time. hopefully it doesn't.

Nice! If you do observe pump-out type issues (rising temperatures in a few months) please report back and alert the community

I wonder, how big a market for this is. I suppose, that would be interesting for Intel as well. all those people doing it wrong and buying part again. good for business, I guess. Make it a TV show, nation wide, so people could have a new hobby.Love it. Wish the air-cooler guys like Noctua would get on this as well

So step reduces the gap? In other words, how can I reduce the gap while retaining the stock TIM? I'm going to guess 'black gluey stuff'

tigersty1e said:there's a scenario I think would give better temps.

the mobo clamp is pushing down on the sides of the ihs and now that the glue is gone, the ihs gets pushed to the PCB and this creates a convex bow right over the CPU.

I'm thinking that we should just remove the mobo clamp and use the cooler mounts to secure the cpu to the mobo. the his will sit flush on the die and possibly never touch the PCB ( although with 50+pounds of mount pressure that is questionable)

Posted from Anandtech.com App for Android

there's a scenario I think would give better temps.

the mobo clamp is pushing down on the sides of the ihs and now that the glue is gone, the ihs gets pushed to the PCB and this creates a convex bow right over the CPU.

I'm thinking that we should just remove the mobo clamp and use the cooler mounts to secure the cpu to the mobo. the his will sit flush on the die and possibly never touch the PCB ( although with 50+pounds of mount pressure that is questionable)

Posted from Anandtech.com App for Android

Idontcare said:Quote:

Originally Posted by tigersty1e

there's a scenario I think would give better temps.

the mobo clamp is pushing down on the sides of the ihs and now that the glue is gone, the ihs gets pushed to the PCB and this creates a convex bow right over the CPU.

I'm thinking that we should just remove the mobo clamp and use the cooler mounts to secure the cpu to the mobo. the his will sit flush on the die and possibly never touch the PCB ( although with 50+pounds of mount pressure that is questionable)

Posted from Anandtech.com App for Android

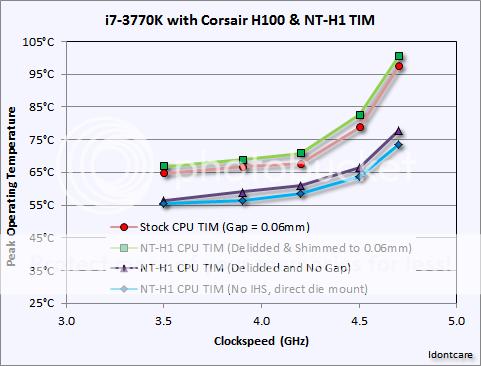

There isn't much thermal performance left on the table after you've delidded and replaced the stock CPU (and reduced the gap).

Going to the extreme of removing the clamp and the IHS entirely, mounting directly to the die, only improves on temps by a few degrees.

IMAGE#1

First time I have seen a reference as to the reason for use of thermal paste on IB...

http://www.tweaktown.com/articles/5...rements-and-overclocking-thoughts/index2.html

"What this means is your Sandy Bridge and Ivy Bridge coolers should work fine with Haswell. Since this is a new product Haswell should have a more efficient IHS when compared to Ivy Bridge. Intel ran into a little issue with the processor core and the IHS. At one time it was reported the issue had to do with using thermal paste instead of soldering the core to the HIS, but later we learned a thermal paste had to be used because the core didn't make good contact with the metal top."

As an engineer I can fathom a number of different thermo-mechanical stress related reasons why Intel might have been compelled to abandon metal solder in favor of the TIM-paste approach, but the one given there by tweaktown just makes no sense.

Making "good contact" is a very simple matter of surface engineering, I can't understate how simplistic of a process that is. It is so simple that Intel had no issue doing it in years past.

To say they couldn't do it with IB is virtually unbelievable. I mean sure it is possible, in the down-right mentally deficient "der, I haz brain-damage and cants git'r'dun" sort of engineering challenge, that is possible and cannot be ruled out, but not in a "all of our collective rocket scientists were totally stumped by this challenge!" manner.

The silicon backside of IB is the same as SB. The 22nm stuff, including the finfets, is all on the other side of the chip, opposite to the surface that is being mated to the IHS. If they had a process that enabled soldering the chip to the IHS with 32nm then that same process would work for 22nm, the solder and the IHS don't know 32nm from 22nm.

red454 said:Quote:

Originally Posted by Idontcare

As an engineer I can fathom a number of different thermo-mechanical stress related reasons why Intel might have been compelled to abandon metal solder in favor of the TIM-paste approach, but the one given there by tweaktown just makes no sense.

Making "good contact" is a very simple matter of surface engineering, I can't understate how simplistic of a process that is. It is so simple that Intel had no issue doing it in years past.

To say they couldn't do it with IB is virtually unbelievable. I mean sure it is possible, in the down-right mentally deficient "der, I haz brain-damage and cants git'r'dun" sort of engineering challenge, that is possible and cannot be ruled out, but not in a "all of our collective rocket scientists were totally stumped by this challenge!" manner.

The silicon backside of IB is the same as SB. The 22nm stuff, including the finfets, is all on the other side of the chip, opposite to the surface that is being mated to the IHS. If they had a process that enabled soldering the chip to the IHS with 32nm then that same process would work for 22nm, the solder and the IHS don't know 32nm from 22nm.

Yep - I'm and engineer too (mechanical) and you have to wonder what changed. If it has worked for so many years, why the shift? Did the bean counters get involved?

To say they couldn't do it with IB is virtually unbelievable. I mean sure it is possible, in the down-right mentally deficient "der, I haz brain-damage and cants git'r'dun" sort of engineering challenge, that is possible and cannot be ruled out, but not in a "all of our collective rocket scientists were totally stumped by this challenge!" manner.

i have clu coming soon. i'll be using it directly on the die.

are there pump-out problems with using regular tim on top of the ihs?

should i also go ahead and put the clu on my ihs?

I thought my CPU was a goner when I accidentally exposed some copper bling from the PCB. This is prior to cleanup of PCB.. Once I came to my senses, got the correct exacto blade, and began to use caution... I tried a couple things to easily remove the black glue... Mass air flow cleaner.. IPA on roids... Works wonders, just don't even think of flames/sparks.

I haphazardly put everything back together, expecting a no-boot or fire... To my surprise, it worked perfectly. Without lapping the IHS or the h80 contact plate.. I even dropped (and subsequently dinged the IHS).. Peak temps dropped by 10-12c.. Idle by about 4c... This is at 4.66ghz... LLC set aggressively on stock voltage (so under load voltage gets high).

The most important improvement (for me) is the elimination of what could be described as temperature creep (under continuous load, be it partial or all cores).. Before this, the temperature ceiling would slowly rise from 70 to high 70s.. Now, 70 is the max.

Again, this setup is somewhat botched - yet somehow greatly improved over stock.. So there you have it, the worst case scenario.