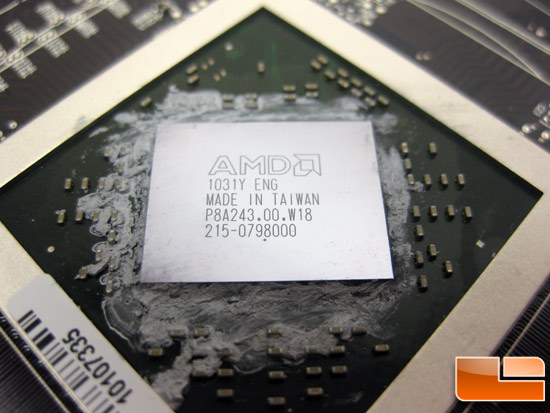

Thought I'd throw in some minor data from an AMD delid of an A10-7700k. Lots of people are looking at delidding Kaveri chips since they have a notorious clockspeed wall which may or may not be related to thermals.

So I did mine with an x-acto knife, which worked out fairly well. I nicked it a few times on the outer edge of the pcb which has caused no known CPU malfunction. Also bent a few pins with my hands (oops) which I bent back. I lapped the ihs to 400 grit only which got all the nickel off and put a blurry shine on most of it. Then I relidded the CPU using CLU all around.

Temps got much worse. Thermal throttling @ 4.5 ghz, etc.

I double-checked my work muchly much later (was very busy) and discovered that the TIM contact pattern was obviously quite poor between the underside of the IHS and the die. Only the dead center of the die seemed to have any contact. This was painting an incredibly thin layer on the die and another on the underside of the IHS, which is my usual application technique with CLU. I added a wee bit more to the die + underside of the IHS (I ran out of CLU in the process, boo), and temps are better but still slightly worse than they were before the relid.

So, I am thinking that Idontcare's observations about CLU usage may also apply to relid operations.

I have more CLU coming and it should get here in a week or two. Will post further results as I get them.

These noobshields should be optional (hint, hint Intel please offer a "mobile" K series).