- Oct 9, 1999

- 5,104

- 3,634

- 136

With the release of Alder Lake less than a week away and the "Lakes" thread having turned into a nightmare to navigate I thought it might be a good time to start a discussion thread solely for Alder Lake.

Yes, flimsy motherboards. $210 flimsy motherboards.Yeah LGA1700 bends.

The last time this came up, it was explicitly stated to only matter if you're lapping the heatsink.

Like spoons?'

Like spoons?'

The best result can be achieved in our tests with a thickness of 1.0 mm with 70.88 °C and thus an improvement of 5.76 °C

What do you mean? This addresses the same thing as the washer mod. Both have been tested to be, at best, a few degrees difference with a particular flat waterblock. More mainstream cooling like AIOs and air coolers will see negligible difference.Wait what?

What do you mean?

The IHS is getting bent, leaving an airgap. It should be serious but only around a 5 degrees celsius improvement with washer mod? Doesn't make sense. The gap should reduce heat dissipation significantly but apparently, that's not happening.I mean where are you getting the lapped heatsink thing? It's not a bowed IHS, it's a bent socket.

The bent heatsink is only a problem if you have a perfectly flat heatsink, which likely means a lapped heatsink. Most consumer heatsinks are already curved (convex) for exactly this reason, to maximize contact area with the slight curvature of the Intel heatsink. This is not something new, heatsink curving on Intel (and sometimes AMD) sockets has been around for a long while now. This includes DIFFERENT types of bending depending on socket (convex, concave, double wave), it all depends on the type of socket retention.I mean where are you getting the lapped heatsink thing? It's not a bowed IHS, it's a bent socket.

The Noctua NH-D15 heatsink has a machined nickel-plated copper baseplate with a surface roughness of approximately ~16 microinches. The base plate is machined perfectly flat in one axis and very slightly convex in the opposite.

The Noctua NH-D14 heatsink has a machined nickel-plated copper base with a surface roughness of approximately ~16 microinches, which is considered very good. The base plate is machined flat in both axis.

Why is the cooler’s contact surface slightly convex?

As the Integrated Heat Spreaders (IHS) of today’s CPUs are slightly concave, the cooler’s contact surface has been deliberately designed to be slightly convex in order to ensure optimal contact. This way, more contact pressure will be applied at the centre of the IHS directly above the DIE, which results in better heat transfer and improved overall performance.

Apart from that, lapping the CPU/ IHS outside the socket doesn't help, as it gets deformed once installed inside the socket. If you would like to have the best performance with a lapped heatsink, you would have to flatten the CPU when it is installed inside the socket.

Someone tell Uri Geller he won't be the laughing stock of tv anymore!Only it doesn't require you to be telekinetic.

The IHS is getting bent, leaving an airgap.

The entire IHS is bending? I doubt that!

Our internal data show that the IHS on 12th Gen desktop processors may have slight deflection after installation in the socket.

Reading between the lines here, they are essentially saying “it might bend a little, sure, but that won’t cause it to run outside of its specification.”

It's bending, Oh God, it's bending!

Wouldn't there be more chance of the IHS adhesion getting compromised, essentially delidding the CPU?If the IHS were actually bending, it would crack the solder underneath, and potentially damage the PCB or maybe even crack the die.

Wouldn't there be more chance of the IHS adhesion getting compromised, essentially delidding the CPU?

Intel Comments on Alder Lake CPU Socket Flexing

According to Intel some warping is expected, but it shouldn't cause much concern.www.extremetech.com

It's bending, Oh God, it's bending!

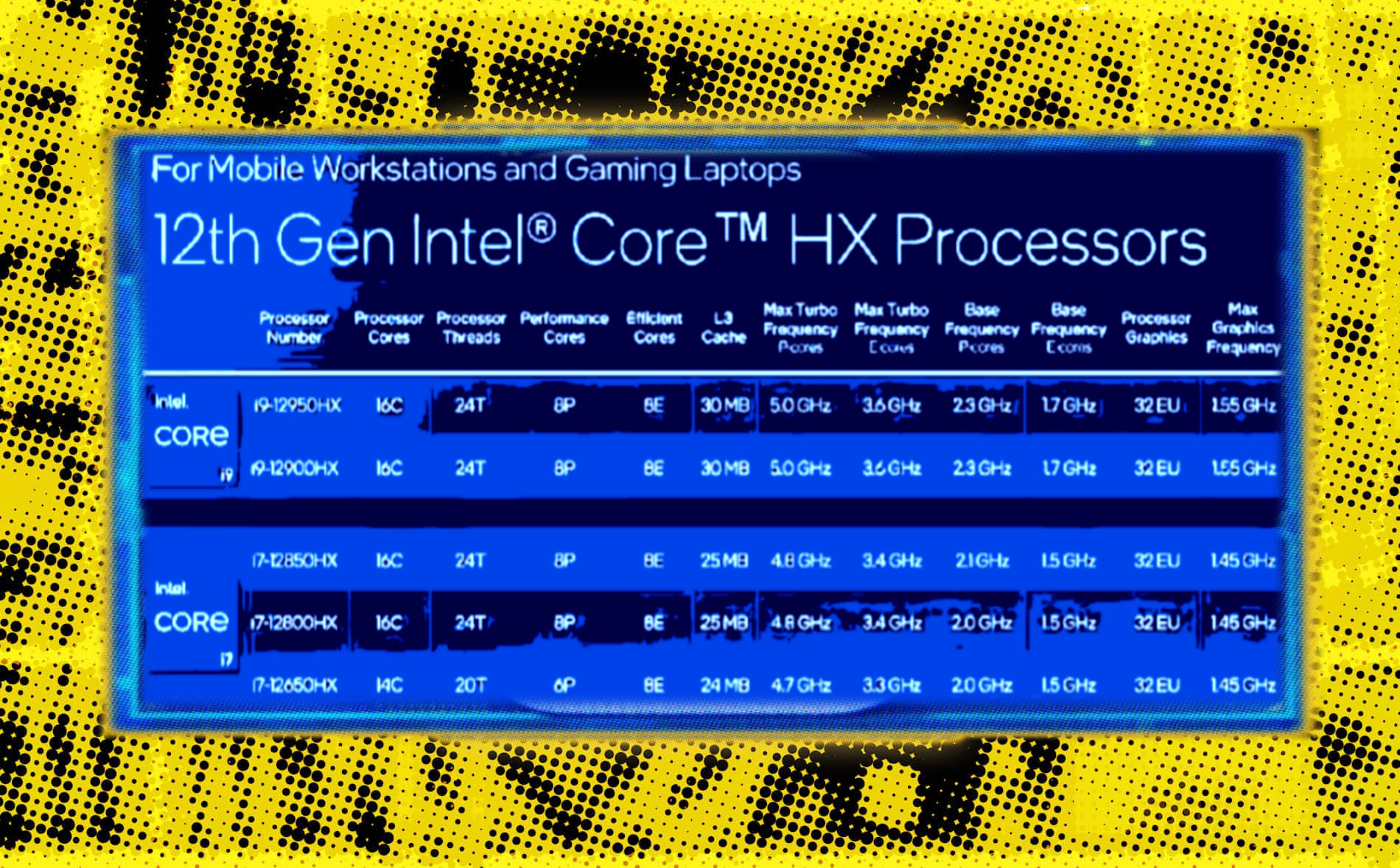

Alder Lake HX's final specs leak. Max turbo power is 157 W. Launch is on Tuesday.

Not surprising since there isn’t a much situation where both the CPU and the GPU bring pushed to a max power at the same time.

MSI unveils Titan GT77 and Vector GP76 gaming laptops with up to Core i9-12900HX, RTX 3080 Ti graphics and 250W power - VideoCardz.com

MSI shows off next-gen mobile gaming laptops The ultra-high-end laptop market is growing by the day. MSI is set to launch its new TITAN, VECTOR, RAIDER and CREATOR laptops very soon. In total there are four new designs all equipped with Intel 12th Gen Core Alder Lake-HX processors and up to...videocardz.com

Here's an example of an 150 W 12900HX and 150 W 3080 Ti mobile. Sounds like you "only" get up to 250 W between the two though.