- Jan 30, 2008

- 3,261

- 12

- 81

As some of you may know my engine rebuild is in full motion at the moment. I just recieved all the parts I need (minus flywheel bolts) to start assembly!

A member of another forum suggested that before I reassemble my head I should Lap the Valves. Me being open to suggestions and curious to what Lapping is decided, "heck why not".

What is Valve Lapping?

Valve Lapping is basically sanding down the surface of the Valves (which allow fuel and air to flow in, and exhaust to flow out) and the Head (Holds the Camshafts and valves) where they make contact with each other. This is done by applying a Compound Paste (pretty much just oil and a fine grade of sand) to the edges of the valves and spinning them in their seats on the head.

What are the benifits of Lapping?

The two that I am aware of are

1) creates a better seal between the valve and the head, which will prevent gases from escaping during the compression stroke of your engine.

2) the greater contact area allows for more heat dissipation from the valves to the head which will prevent burnt valves.

Here are my results:

Below are two INTAKE valves. The valve on the left has been lapped. The valve on the right has not. The contact surface of the valve has been put into brackets. You can see that the lapped valve has about a %50 increase in surface contact area. Good stuff!

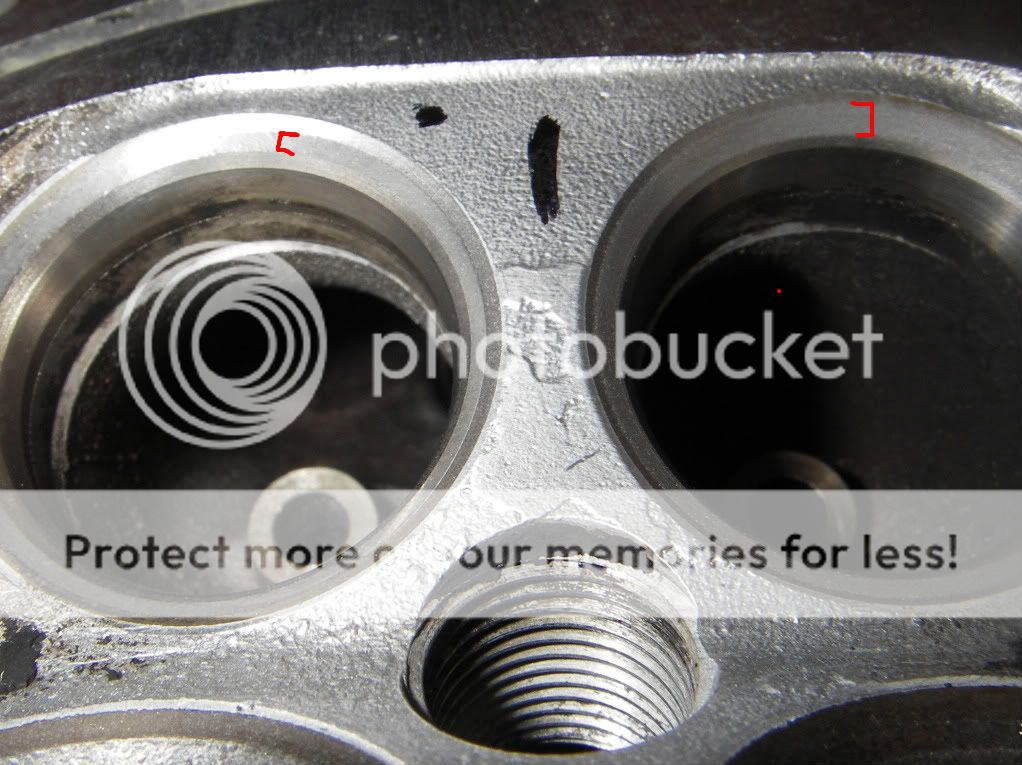

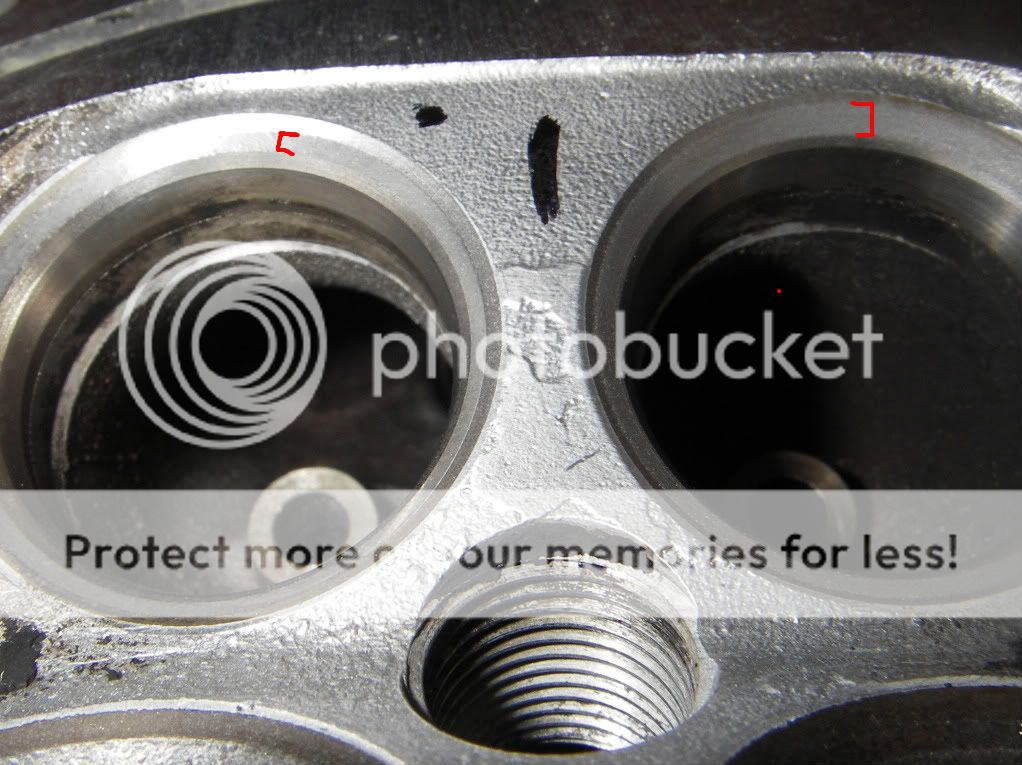

Here is the corresponding seats on the head. The seat on the right is lapped, while the seat on the left is not lapped.

Now those were the INTAKE valves. The EXHAUST valves had much more noticable results.

On the left is a lapped exhaust valve. on the right, unlapped

The left is a lapped seat, the right is not lapped.

From what I can tell, my valve lapping session was a complete success. If anyone intends of ever doing this, it is highly advised to not allow any compound to be left anywhere as you do not want any of this stuff to be left over to possibly attach itself between the piston rings and the cylinder wall. Also do not allow compound to enter into the areas up by the valve seals. Creating friction in these areas is bad bad bad.

Also, here is a short video of me turning two different valves. The first valve is unlapped and the sound while turning is grindy and sticky (you'll hear it :awe The second valve is lapped and the sound while turning is smooth.

The second valve is lapped and the sound while turning is smooth.

http://www.youtube.com/watch?v=M2lnwLJXrZg

A member of another forum suggested that before I reassemble my head I should Lap the Valves. Me being open to suggestions and curious to what Lapping is decided, "heck why not".

What is Valve Lapping?

Valve Lapping is basically sanding down the surface of the Valves (which allow fuel and air to flow in, and exhaust to flow out) and the Head (Holds the Camshafts and valves) where they make contact with each other. This is done by applying a Compound Paste (pretty much just oil and a fine grade of sand) to the edges of the valves and spinning them in their seats on the head.

What are the benifits of Lapping?

The two that I am aware of are

1) creates a better seal between the valve and the head, which will prevent gases from escaping during the compression stroke of your engine.

2) the greater contact area allows for more heat dissipation from the valves to the head which will prevent burnt valves.

Here are my results:

Below are two INTAKE valves. The valve on the left has been lapped. The valve on the right has not. The contact surface of the valve has been put into brackets. You can see that the lapped valve has about a %50 increase in surface contact area. Good stuff!

Here is the corresponding seats on the head. The seat on the right is lapped, while the seat on the left is not lapped.

Now those were the INTAKE valves. The EXHAUST valves had much more noticable results.

On the left is a lapped exhaust valve. on the right, unlapped

The left is a lapped seat, the right is not lapped.

From what I can tell, my valve lapping session was a complete success. If anyone intends of ever doing this, it is highly advised to not allow any compound to be left anywhere as you do not want any of this stuff to be left over to possibly attach itself between the piston rings and the cylinder wall. Also do not allow compound to enter into the areas up by the valve seals. Creating friction in these areas is bad bad bad.

Also, here is a short video of me turning two different valves. The first valve is unlapped and the sound while turning is grindy and sticky (you'll hear it :awe

http://www.youtube.com/watch?v=M2lnwLJXrZg

Last edited: