I didnt know fabs had such leeway in linewidths. I thought a 45nm facility would absolutely only produce 45nm but could potentially churn out GPUs, CPUs and SSDs.

I must be mistaken

If you don't work in the industry it is easy to get this impression from the way the press and the media talk about technology transitions and process nodes. So don't feel bad or think you missed out on something obvious.

Fabs can in fact, and routinely do so, produce products on multiple nodes in parallel at the same time.

Think of it like McDonalds or Burger King. They have a "burger station" in the back, even if you haven't worked at a fast food restaurant you've probably been to one enough times to have basically witnessed how they prepare the food.

Now this "burger station" has all the condiments needed to make different burgers. Ketchup, pickles, cheese, etc. And from that one burger station they can create all the different items on the menu. Some of those items use the same ingredients. Order a chicken sandwich or hamburger and the people in the back are going to need to use the same mayo and the same lettuce for both.

Process nodes and fabs are a lot like this. Each piece of equipment in the fab, we call them "tools" in the industry, is capable of doing many different processes, we actually call these "recipes" in the industry.

Think of it like a blender or a mixer, the recipe calls for the specific ingredients to be added to the mixer - 1 cup flour, 1/2 cup sugar, etc - depending on what it is you intend to make with the batter. Pancakes would use different ingredients and quantities than say biscuits or a cake.

So we use these "tools" (the blender/mixer) combined with specially engineered "recipes" on any given batch of wafers (we call them "lots") depending on what process node the wafers belong to and what step in the process flow the wafers are at. A batch of 90nm wafers may need a 60 second dip in phosphoric acid while the next batch of wafers to show up at the tool are 45nm wafers that need a 15 second dip in phosphoric acid (or could even be a different acid altogether, but still processed on the same tool).

A mature fab that has been around for 10yrs will probably have 5 or 6 nodes running in parallel.

Now a

BIG difference comes in when we talk about different

types of process nodes. Memory versus logic. Flash, dram, cpus.

A process node developed to make dram cannot be used to make flash, you need specialized features to make flash that are not present in dram. We call these "components" in the industry. Same with logic.

A logic process node can't be used to make dram because the logic node will have been developed without trench capacitor components. If you wanted to make dram with the logic node you would need to further develop all the specialized components that make dram different from cpus.

That McDonald's burger station could be used to make Arby's roast-beef sandwiches but they don't have the necessary ingredients (sliced roast beef versus ground hamburger) to create a roast-beef sandwich.

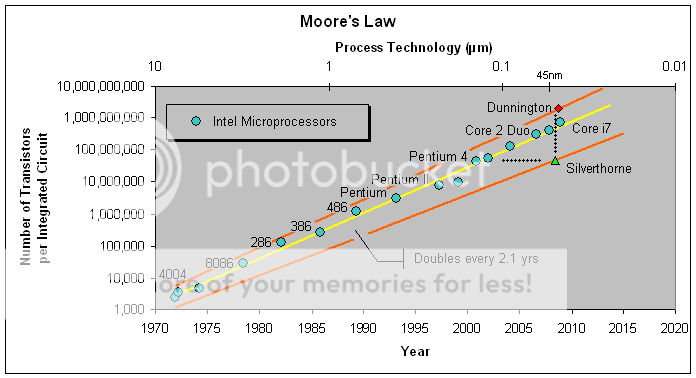

edit: this is a somewhat dated graphic by now, needs some updating, but you see all those nodes that are still in production at TSMC? Those all run in parallel in about 3 different fabs. The older nodes aren't qualified in the newest of fabs of course, but they just add the newest node to the pre-existing fabs by installing a few unique and enabling tools (like immersion litho) in the pre-existing fab, requalify all the existing tools with the new recipes and start ramping production.