Turns out doing a direct-die mount of your HSF onto an Ivy Bridge chip is rather easy to do.

What isn't easy to do is getting the right amount of downforce on the CPU such that everything is copacetic.

Here's the socket bracket, simple star-key type bolts, took all of about 15 seconds to remove the entire socket bracket assembly.

Next item on the agenda was setting up the H100 with mounting bolts that don't have the standoffs that are too high given that the IHS won't be there anymore.

This turned out to be rather easy to solve, a trip to Home Depot for some #4-40 bolts was all it took. I threaded them up through the H100's support bracket from behind the mobo (silvery bolts in the picture below).

You can tell in the pic above that I really slathered on the NT-H1 TIM for this test in hopes of having the TIM serve a dual-purpose of thermal conductor as well as being a springy-spongy mass of sorts to dampen the inexperienced hands that were about to slam an H100 waterblock down onto the that bare silicon die :whiste:

Once the H100 was placed on top of the die I proceeded to add washers and nuts (inner diameter of the nuts was > the #4 bolt diameter, they are there truly as nothing more than standoff shims) until the remaining bolt length was just right for me to use the H100's stock mounting thumb-nuts (is that even a word? it feels wrong to write it

).

Now then, getting this to boot was a real trick. And keeping it from rebooting was yet another trick. I intended to put a spring on the bolt to provide some resistance to the thumb-nut torque but I got lazy and just went straight for the kill.

The result is that the operating temperatures were very sensitive to how much I tightened those thumb-nuts (as one would expect), but it was also very easy to overtighten them and cause the system to reboot (and promptly hang, BIOS gave an error code that ASUS claims means "no memory installed").

How sensitive are we talking? At 3.5GHz with the initial tightness my peak temperatures were 67°C. I tightened the thumb-nuts by a mere 180° (half a turn) and the peak temps reduced to 61°C. So I turned them another 180° only to have that cause the computer to spontaneously reboot. I backed the nuts off by 90° and the system booted and the peak operating temps were a mere 55°C.

That is a huge range in operating temperature for what amounted to less than a single full turn of the H100 mounting nuts, and going just a smidgen too far and the system reboots. Very touchy.

That said, what kind of results were I able to arrive at with my new found finicky friend?

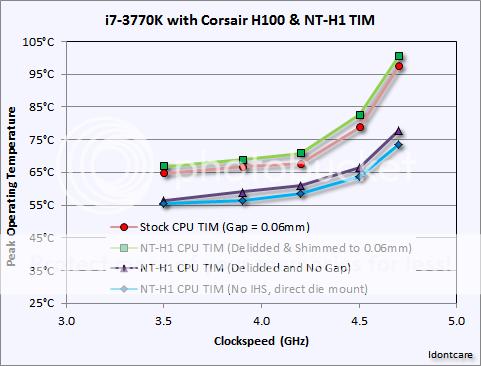

^ compare cases "c" to that of cases "d" to see the improvements I observed in removing the IHS entirely from my system. In general I only benefited by a few degrees.

Now I realize throwing a big'ole table up like that will basically make people's eyes glaze over, so here is a graph of the same results:

The take home message there is replacing the CPU TIM doesn't really provide any benefit. Reducing the gap between the CPU and the IHS does. And removing the IHS entirely doesn't really provide much benefit either.

And that stands to reason. The heat is going to flow through the copper of the IHS the same as it does through the copper of the H100 waterblock.

But if there is a thick pad of thermal paste in the way, as was the case with my 3770k at time of purchase, then it doesn't really matter how good the TIM itself is (unless it too is made of metal) because the mere presence of that thick pad of thermal paste becomes the weakest link in the thermal conductivity equation.

Once you eliminate the bottleneck that is the gap between the IHS and the CPU, or if you happen to end up with an Ivy Bridge CPU which doesn't have much of a gap to begin with (Yuriman

), then you have pretty much optimized the system at that point regardless which CPU TIM of choice you employ and regardless whether or not you leave the IHS in place.

Now the choice of CPU TIM still plays a role in terms of the robustness in maintaining those nice low temperatures. If the so-called "pump out" effect is real then we can expect it to bite us unless we choose a substitute CPU TIM that is designed to avoid such thermo-mechanical effects.

I haven't really got into testing that part out yet, but I expect IC Diamond and the metal TIMs like Liquid Ultra to be key there.