Did you

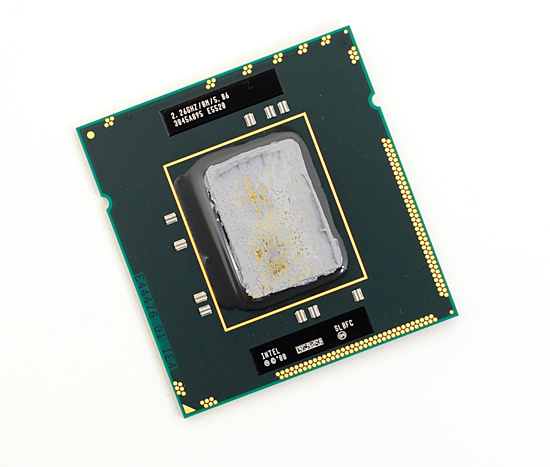

remove all the IHS adhesive (the black stuff) from both the PCB and the IHS?

When you have no CPU paste on the CPU or the IHS, can you

freely spin your IHS? (meaning it is not making contact with the PCB)

The next thing to be careful about is on the PCB where the black rectangle is with the writing on it, that is a raised area. Do not let your IHS slide up onto that when securing the socket retention bracket (you will notice the bracket pushes the IHS in the direction of the latch).

If the IHS slides up onto the bevel of that black rectangle then you will be creating a larger gap between the IHS and the CPU.

The other thing to check is the amount of TIM paste you are using and the type. If you have access to any other type you should at least try it to see if it makes a difference.

With my 3770k, by far and away the one thing that changes my operating temps the most is the gap between the IHS and the CPU.

The only time I see my 20C decrease in temps is if I let the IHS make direct contact with the die (with TIM inbetween of course). As soon as I do anything to lift the IHS off of the CPU, using metal shims or paper shims, the temperatures go crazy high.

So my advice to you is to get to know the gap between your CPU and IHS and figure out what it will take for you to eliminate it.

My next tests wiil be testing without the IHS. First though I have to repair my H100. I used that IC Diamond stuff for one test with the IHS and holy crap if it didn't corrode the bejesus out of the copper surface on my H100 and my IHS. It also scratched the CPU silicon die itself.

I'm rather pissed about that because I had my reservations and yet the IC diamond guy convinced me it wouldn't happen. But there it is, a big old scratch right on my chip and now the materials science education in me tells me exactly what that crack is going to do to the rest of my chip

I've no one to blame but myself though, I knew better but I did it anyways.