richierich1212

Platinum Member

- Jul 5, 2002

- 2,741

- 360

- 126

Here's one that IDC did on lapping his H100. link

What kind of voltage did you need for 4.8 GHz? 4.7 GHz at 1.256v seems pretty reasonable, and that's a little beyond what most Sandy Bridge cores will hit on reasonable voltage. Above 4.5 GHz, my i5-2500K needs pretty major voltage jumps to remain stable. 4.4 GHz will run stable at 1.3v (~1.36v before Vdroop), but 4.5 GHz requires ~1.34v after Vdroop. Above that, I have to jump to >1.4v, which I'm not comfortable with.

You may be showing us that Ivy Bridge scales slightly better than Sandy Bridge. Sandy Bridge usually makes it to 4.4-4.6 GHz relatively easily, but 4.7-4.8 GHz usually require high voltage. 4.9-5.0 GHz is probably attainable on a large portion of Sandy Bridge cores, but the voltage required is far out of the "safe" range. If Ivy Bridge manages 4.7-4.9 GHz pretty consistently, then no complaints of Intel's 22nm process being a failure are valid.

So I pulled off the H100 and unmounted the IHS to move on with the next test - using the Intel CPU TIM from under the IHS as a TIM on top of the IHS of my 2600k for a comparison with other TIMs. (i.e. the "is that CPU TIM crappy stuff, or good stuff?" test)

Amazing.

Just amazing!

So much for all the people posting saying that IB higher temps were due to the smaller node concentrating the heat and not allowing it to dissipate effectively. Morons.

Next up, direct core cooling and then one of the liquid metal TIMs. Cannot wait.

Awesome work IDC!!!

This doesn't make thermal density any less relevant. Even after he's done all of this, his CPU is running hotter than my 4.4 GHz 2500K on a Hyper 212+ with all my case fans on low. While LinPacking, my CPU never breaks 70C.

That's with a cheap air cooler and Arctic Silver 5 I bought in 2005 to put on an Athlon 64.

So much for all the people posting saying that IB higher temps were due to the smaller node concentrating the heat and not allowing it to dissipate effectively. Morons.

If a good aftermarket TIM under the IHS would make such a huge difference in temps, would that mean that Intel is using the cheap stuff? :hmm:

We don't know whether Intel considered diamond paste, whether there is some "risk" of using micronized diamond (not too likely), whether they looked at the other exotic "metal" TIMs. IF it adds to their costs, choosing a less costly solution is their prerogative, and makes business sense. It makes business sense if the majority of processors you sell are going to OEM makers.

If a good aftermarket TIM under the IHS would make such a huge difference in temps, would that mean that Intel is using the cheap stuff? :hmm:

Amazing.

Just amazing!

So much for all the people posting saying that IB higher temps were due to the smaller node concentrating the heat and not allowing it to dissipate effectively. Morons.

Next up, direct core cooling and then one of the liquid metal TIMs. Cannot wait.

Awesome work IDC!!!

But he's not running at 4.4. The crucial speed or the one of most interest so far is 4.7. My cores go to almost 74C at 4.6 (i7-2600K) under full load with NH-D14 and diamond paste. They're well over 80C at 4.7. And IDC isn't even testing "best" TIM yet, while those untested options promise further improvements of 5C or more -- my guess.

Keep in mind that -- yes, there's been a die-shrink to 22nm process, but the TDP has also come down from 95W to 77W. So thermal density is "important," but it is one of several factors.

thermal density increased close to 10% temped skyrocket even more

well i read some post in this forum and there was a person asking the same question okey the area in smaller but also the comsumption so that balance more or less each other. and they accused him nope you do not know what you say.

i think it is beyond any doubt any longer ivy is hotter cause intel squeezed a peny or intel wanted the people not able to overclock ivy that much.

I think notcase closed

Loland some apologies much be given to some people attacked so furiously in these forums

But he's not running at 4.4. The crucial speed or the one of most interest so far is 4.7. My cores go to almost 74C at 4.6 (i7-2600K) under full load with NH-D14 and diamond paste. They're well over 80C at 4.7. And IDC isn't even testing "best" TIM yet, while those untested options promise further improvements of 5C or more -- my guess.

Keep in mind that -- yes, there's been a die-shrink to 22nm process, but the TDP has also come down from 95W to 77W. So thermal density is "important," but it is one of several factors.

At 4.7 GHz, I have to push my voltages to the point I hit around 78 C. My CPU certainly isn't blowing up, but the voltages required are higher than I'd like. This is on a Hyper 212+, however. An H100 would run significantly cooler.

All IDC has done is show that poor thermal compound is an issue on his unit. There have been reports of some Ivy Bridge CPUs responding relatively poorly to a change in TIM. This definitely shows what a poor paste job can do, but it doesn't make thermal density any less of an issue.

That said, this is a perfect example of what could potentially happen when you go beyond what the manufacturer intends. A 20 C drop in temperature and bypassing previous thermal limitations on your CPU - definitely nice.

Also, to all conspiracy theorists: Ivy Bridge is subject to increased thermal density. It isn't a conspiracy. The lack of consistency in temperature drops from applying new TIM to the IHS further disproves this ridiculous conspiracy. If anything, all you're showing is that Intel's manufacturing process isn't great, not that they're conspiring behind your back.

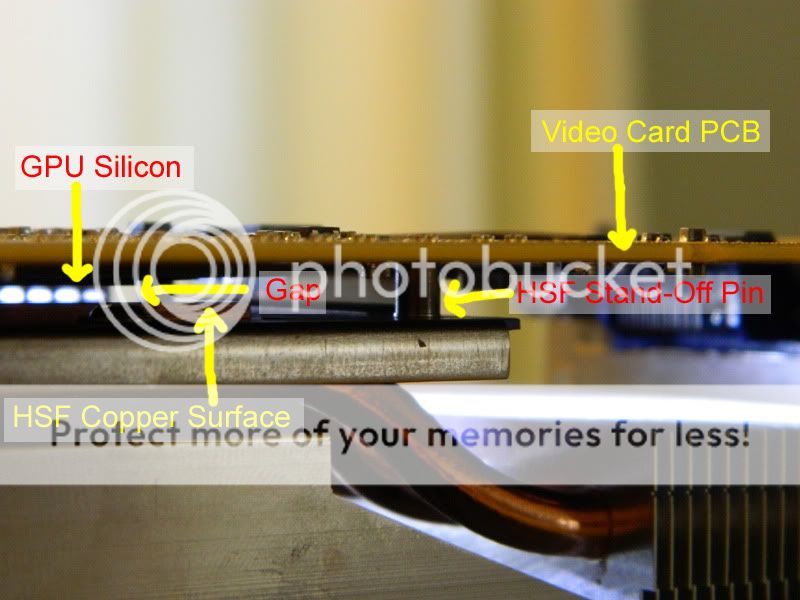

When you put the IHS back on your chip, was there any gap at all between the lid and the PCB? I'm concerned that the IHS might rock and crush a corner or edge because there isn't black goop filling that space and preventing it from rocking.

What was the stable load voltage (anything that survived a prelim IBT or LinX test) @ 4.9 with the i7-2600K? Wasn't the successive voltage increase for i7-2600K between 4.7 and 4.9 Ghz rising steeply?

The i7-2600K apparently overclocks to 4.9Ghz with approximate load voltage in the 1.44 to 1.46V range. In any event, it is above 1.41V.

So if IDC OC'd an i7-3770K chip at 4.9 with about 1.37+V, it doesn't seem like much of an advantage. . . .

from these photos we can clearly make out that IDC runs his own fab facility in his basement. He is currently manufacturing 14nm chips and is developing a 10nm in his spare time for his own personal use using EUV lithography (also developed in his spare time)

in this photo we can see him working on a prototype OLED Ipad4 display. We see he is of asian descent, clearly only the finest genetic material is part of IDC's genome.

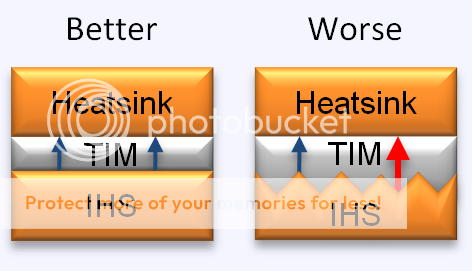

to play devils advocate, having /\/\/\/\/\/\/\/\ as in with an unlapped surface vs __________ with lapped would increase the surface area, allowing for greater thermal dissipation....if you could get the thermal compound into those grooves...no?

This is quite amazing. Thanks for all the hard work!

What I don't understand is how that razor blade didn't hit the die, which I assume is not flush with the PCB, when cutting the stock TIM.

BTW, do you have a third hand? No other explanation for how you got those pics!

Sticky. But you must finish this.

I'm surprised you got so much done while getting so much documented, videoed and photographed.

Do you have any indication that perhaps the Intel TIM is really AS5?

I also tried a carbon based pastes, mx4 and NT-H1. Both of these gave inferior results compared to AS5. You have any to try?

Is there a reason you haven't tried direct die contact? I guess it isn't irrational to worry about cracking the die, but we've all mounted a Coppermine or K7 back in the day. I don't see why it would be any more dangerous now.

I'm also interested in this part of the testing. Did you post results yet or are you holding out on them? Wondering if it's a combo of the TIM being not so good and possibly the bonding agent for the heatspreader increasing the gap too much.

Interesting results so far

What kind of voltage did you need for 4.8 GHz? 4.7 GHz at 1.256v seems pretty reasonable, and that's a little beyond what most Sandy Bridge cores will hit on reasonable voltage. Above 4.5 GHz, my i5-2500K needs pretty major voltage jumps to remain stable. 4.4 GHz will run stable at 1.3v (~1.36v before Vdroop), but 4.5 GHz requires ~1.34v after Vdroop. Above that, I have to jump to >1.4v, which I'm not comfortable with.

You may be showing us that Ivy Bridge scales slightly better than Sandy Bridge. Sandy Bridge usually makes it to 4.4-4.6 GHz relatively easily, but 4.7-4.8 GHz usually require high voltage. 4.9-5.0 GHz is probably attainable on a large portion of Sandy Bridge cores, but the voltage required is far out of the "safe" range. If Ivy Bridge manages 4.7-4.9 GHz pretty consistently, then no complaints of Intel's 22nm process being a failure are valid.

. . .

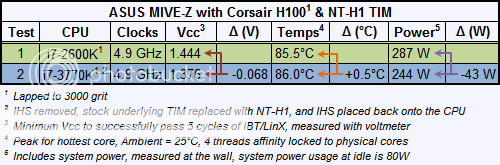

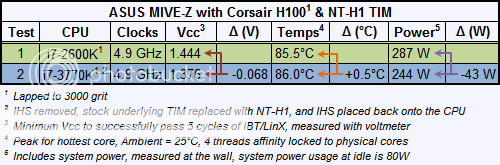

At 4.9GHz, using the same mobo, H100, etc etc, my 2600k requires 1.444V for LinX stability, the tangible benefit appears to be the near 45W reduction in power-consumption when OC'ed to those extremes.

But I don't want to overstate the relevance of the power savings...at the ~$0.10/kWHr rate that I pay here in PA, if I ran my 3770k at 4.9GHz 24hrs a day, every day for an entire year then I'd be looking at saving around $37 for the entire year versus having used my 2600k in the exact same capacity.

I'll take it because I've already bought the chip, but $40/yr is not a decision-making datum point, but it is about the only "plus" to be had in the pro-IB column versus the pro-SB column when it comes to high-end computing performance at high clocks and high operating voltages. (IB wins hands-down when it comes to the other end of the power-usage spectrum, mobile platforms will definitely benefit from IB)

. . .