Edit: Adding direct links to specific posts within this thread that contain specific updates, a table of contents if you will:

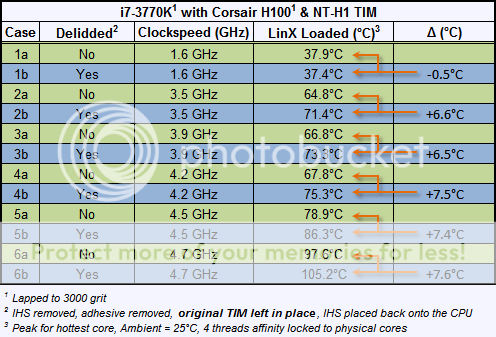

OK, not a big surprise, lots of people have been delidding their 3570k's and 3770k's to replace the thermal interface material (TIM) that Intel puts between the CPU chip and the underside of the integrated heat spreader (IHS)...but after observing no improvement in my 3770k's loaded temperatures after lapping the IHS, I wasn't holding out much hope that my chip would be anything special even with a delidding.

Nevertheless I delidded it anyway, did a bunch of tests but eventually replaced the stock CPU TIM with some noctua NT-H1 thermal paste, put the IHS lid back on and mounted my H100 with some NT-H1 as if the 3770k had never been delidded to begin with.

^ I intentionally used a LOT of NT-H1 on the CPU because there was a large amount of room under the IHS for the excess to go and because I really wanted to avoid risking chipping the corners of my CPU at this early stage of testing after delidding. I'll dial that volume of TIM back down to reasonable levels in later tests.

^ reseated the IHS over the CPU, you really have to "back it up" by initially placing the IHS well off-center so that by the time the socket retention mechanism was done latching onto the wings of the IHS the IHS itself had been pushed into a center position by the latch.

I have lots of pics to share regarding the process involved in obtaining the following results, but first lets just cut right to the it and get the exciting result up front and center!

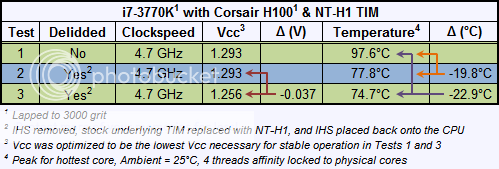

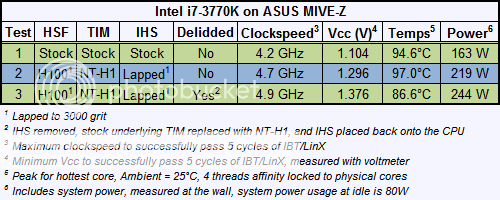

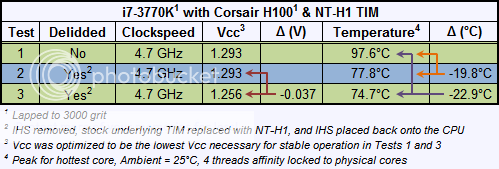

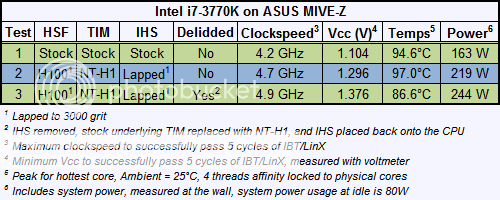

At 4.7GHz, the highest I could overclock my lapped 3770k with a lapped H100 using NT-H1 paste before I delidded, the peak operating temps under LinX are reduced by a rather astonishing 20°C!

Further still, because the operating temperatures had decreased so much, I was able to reduce the required Vcc for maintaining stability by ~0.04V which in turn reduced the operating temperatures by another 3°C :thumbsup:

The reduction in operating temperatures and required voltage came with the added benefit of reducing power consumption of the the CPU by ~10% (more on this later) at 4.7GHz.

Turning this around and asking the question "what can we do with this new found thermal headroom?" I was able to get another 0.2GHz out of the chip while staying within a comfortable operating voltage range.

From an "extra OC'ing headroom" standpoint, popping off the IHS and replacing the Intel stock TIM under the IHS with some NT-H1 and then putting the IHS back onto the CPU results in gaining access to an extra 200 MHz clockspeed without running into the TJmax brick wall, provided you are willing to stomach the elevated power consumption and required voltage to hit 4.9GHz.

(note 5Ghz, LinX stable, is doable but requires an unsettling 1.450V which I would not personally want to use on a 24/7 basis for concerns of voltage-induced degradation)

So the temperature drop is real, the improvement in OC'ing is real, the question would be a matter of "is it worth it"? But that is a universally applicable question to all things OC'ing or enthusiast-like with this hobby.

For all my efforts so far in this project I felt the resultant decrease in operating temperatures was nice but I also felt the improvement in OC'ing headroom was a bit lacking considering I could hit 5GHz on my lapped 2600k with the same mobo and same H100.

But it has been fun, I am actually thankful to Intel that they elected to not solder my 3770k as it gave me a chance to play around "under the hood" as it were. Something I can't do with my 2600k. (speaking of playing around under the hood, more results of that playing around will be forthcoming and posted up in this thread)

- Delidded my i7-3770K, loaded temperatures drop by 20°C at 4.7GHz (that's this post, read below

)

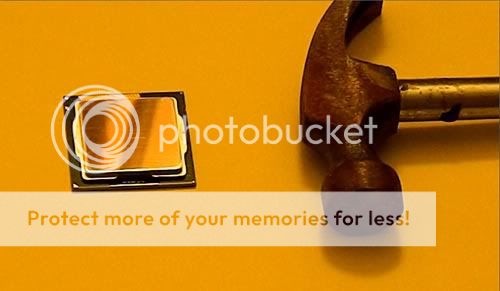

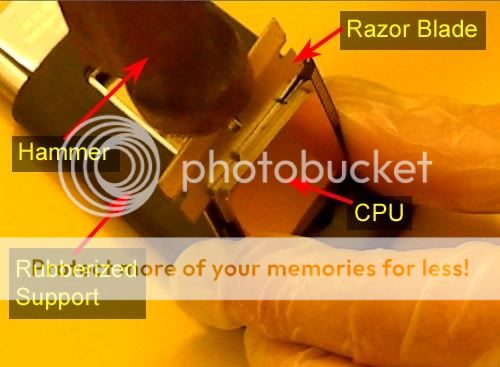

- The "delidding"...now with more hammer!

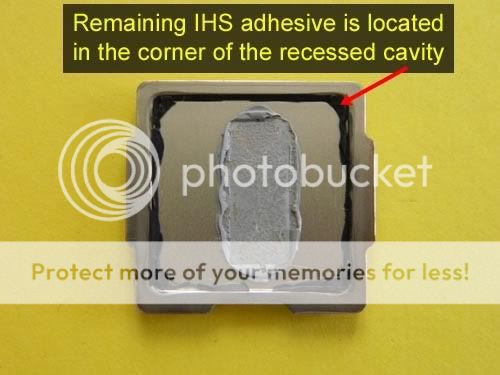

- Removing all that adhesive from under the IHS

- Testing the Intel stock CPU TIM from a delidded 3770k as a HSF TIM to cool a 2600k

- On the topic of thickness measurements and "minding the gap" (part 1 of 2)

- On the topic of thickness measurements and "minding the gap" (part 2 of 2)

- Proof that the benefit from Delidding is entirely due to reducing the CPU-to-IHS gap

- Results of Direct-Die Mount with H100 (no IHS)

OK, not a big surprise, lots of people have been delidding their 3570k's and 3770k's to replace the thermal interface material (TIM) that Intel puts between the CPU chip and the underside of the integrated heat spreader (IHS)...but after observing no improvement in my 3770k's loaded temperatures after lapping the IHS, I wasn't holding out much hope that my chip would be anything special even with a delidding.

Nevertheless I delidded it anyway, did a bunch of tests but eventually replaced the stock CPU TIM with some noctua NT-H1 thermal paste, put the IHS lid back on and mounted my H100 with some NT-H1 as if the 3770k had never been delidded to begin with.

^ I intentionally used a LOT of NT-H1 on the CPU because there was a large amount of room under the IHS for the excess to go and because I really wanted to avoid risking chipping the corners of my CPU at this early stage of testing after delidding. I'll dial that volume of TIM back down to reasonable levels in later tests.

^ reseated the IHS over the CPU, you really have to "back it up" by initially placing the IHS well off-center so that by the time the socket retention mechanism was done latching onto the wings of the IHS the IHS itself had been pushed into a center position by the latch.

I have lots of pics to share regarding the process involved in obtaining the following results, but first lets just cut right to the it and get the exciting result up front and center!

At 4.7GHz, the highest I could overclock my lapped 3770k with a lapped H100 using NT-H1 paste before I delidded, the peak operating temps under LinX are reduced by a rather astonishing 20°C!

Further still, because the operating temperatures had decreased so much, I was able to reduce the required Vcc for maintaining stability by ~0.04V which in turn reduced the operating temperatures by another 3°C :thumbsup:

The reduction in operating temperatures and required voltage came with the added benefit of reducing power consumption of the the CPU by ~10% (more on this later) at 4.7GHz.

Turning this around and asking the question "what can we do with this new found thermal headroom?" I was able to get another 0.2GHz out of the chip while staying within a comfortable operating voltage range.

From an "extra OC'ing headroom" standpoint, popping off the IHS and replacing the Intel stock TIM under the IHS with some NT-H1 and then putting the IHS back onto the CPU results in gaining access to an extra 200 MHz clockspeed without running into the TJmax brick wall, provided you are willing to stomach the elevated power consumption and required voltage to hit 4.9GHz.

(note 5Ghz, LinX stable, is doable but requires an unsettling 1.450V which I would not personally want to use on a 24/7 basis for concerns of voltage-induced degradation)

So the temperature drop is real, the improvement in OC'ing is real, the question would be a matter of "is it worth it"? But that is a universally applicable question to all things OC'ing or enthusiast-like with this hobby.

For all my efforts so far in this project I felt the resultant decrease in operating temperatures was nice but I also felt the improvement in OC'ing headroom was a bit lacking considering I could hit 5GHz on my lapped 2600k with the same mobo and same H100.

But it has been fun, I am actually thankful to Intel that they elected to not solder my 3770k as it gave me a chance to play around "under the hood" as it were. Something I can't do with my 2600k. (speaking of playing around under the hood, more results of that playing around will be forthcoming and posted up in this thread)

Last edited: