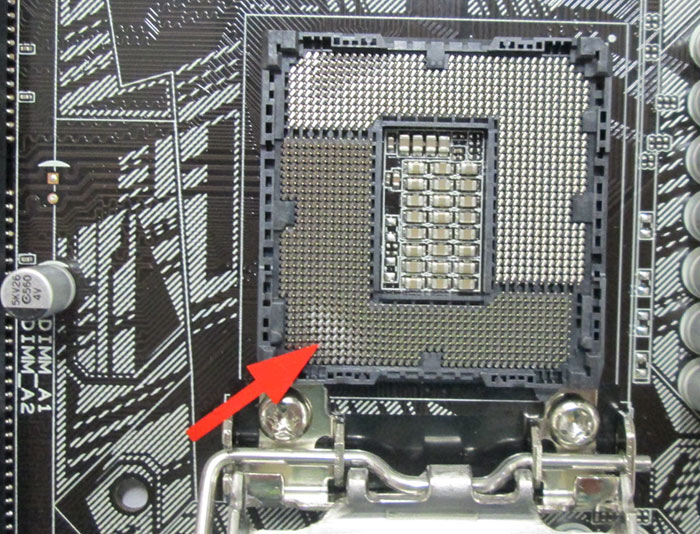

If you get socket damage, it doesn't matter what CPU you used.

torque can also do that...

if u have a heavy heat sink where the weight is at the end, and it torques down, over time it will bend the socket.

Now i just need to see the underside of the board to see if the retension backplate is bent as well to rule anything out.

But technically it shouldn't happen like that, unless something is seriously wrong.

Lastly, heat sinks are no longer flat anymore.

They have a slight bow to apply pressure in the middle to warp the IHS and allow a better mount with IHS + Die.

This has been seen many many times on waterblocks, and infact now all waterblocks have a slight bow.

Any damage to the socket is caused by the CPU - be it directly or indirectly.

this is exactly why we need to see the underside of the board.

need to see if the back retension plate is warped, or bent in any regards.

If the plate is warped, the heat sink mount pressure can be blamed.

If the plate is still fine, then the cpu is most definitely at fault.

It could not withstand the weight of the heat sink in a torque setting, hence the cpu itself started to bow along with the heat sink, which caused socket damage as listed.

This would totally be a manufacturer goof on intel seeing how the cpu itself warped under the weight of the heat sink.

People have bent motherboards, CPUs, and sockets. Chipped dies. Cracked boards, CPUs and sockets etc before due to over tension.

did u even see the damage to the socket?

Again... the rear plate prevents any of that sort from happening.

It forces the cpu to be sandwitched and should not bend the socket like that.

I have placed many many test hours on retension systems with i used to review waterblocks for the community.

Here is an example of extreme overtightening... yet you can clearly see the socket + cpu itself is kept flat..

This is mostly because the mounting holes are outside the socket + cpu area, and the board will rise at the pivot point of the mounting holes, and not the cpu itself.

With a proper backplate, which 95% of intel boards have now a days due to the latch system being built on them, it should of prevented the socket from being damaged like that, unless the said cpu itself became warped under the mounting pressure.