Thanks for the reply IDC. What's the best way to lap an ihs on sandpaper. Some people go up and down, others circular, and some clockwise rotating 45 degrees. Also is using oil and polish really necessary? Finally, could I sand the ihs after I delid, that way I wouldn't have to worry about bending pins?

ha ha, you asked the right person here

This is one place where my college education happen to be perfectly applicable to what we are doing as hobbyists in one-to-one fashion.

My bachelors degree is in Materials Science and Engineering (MSE), and one of the things you get to do for a year while pursuing a BS in MSE is you get to take metals classes that include lab classes - think chemistry class only with smelting liquid metals and so on using mini-furnaces and the like.

Well one full semester of these metals labs is dedicated to learning the proper technique for

preparing metallographic specimens for magnified studies (taking pictures of grain structure under a microscope).

We had to learn all about the proper way to sand, lap, and polish metal to remove scratches (deformed material, undesired metallographic structures), worry about inclusions, pitting, staining, discoloration, parasitic oxidation, etc etc.

So when it came time to apply that knowledge to the growing hobby of lapping my CPU's IHS or my HSF it was second-nature for me.

Now you ask - how do you it then? Well for 220 grit and 400 grit I very lightly wet the sandpaper. For higher grits I use dry sanding only. No oil, ever. You want to use water because it is miscible with IPA and you want to use IPA to rinse and then dry your CPU/IHS between successive grits of sand paper. Oil cannot be fully/easily removed from the surfaces and it will entrain nodules of grit from the prior sandpaper and carry it over to the next higher grit paper, causing inadvertent scratches.

You can get away without using water on the 220 grit and 400 grit if you like, I only use it to prolong the life of the sandpaper itself. The water is not there to help the lapping of the IHS or HSF.

I intentionally do not use water above 400 grit because the surface cohesion of the water actually makes the surface of your IHS or HSF stick to the paper and you will notice it starts to stick and then skip off the paper. This is actually causing more work for you because the skipping creates even deeper scratches that must then be removed at higher grits with added lapping time.

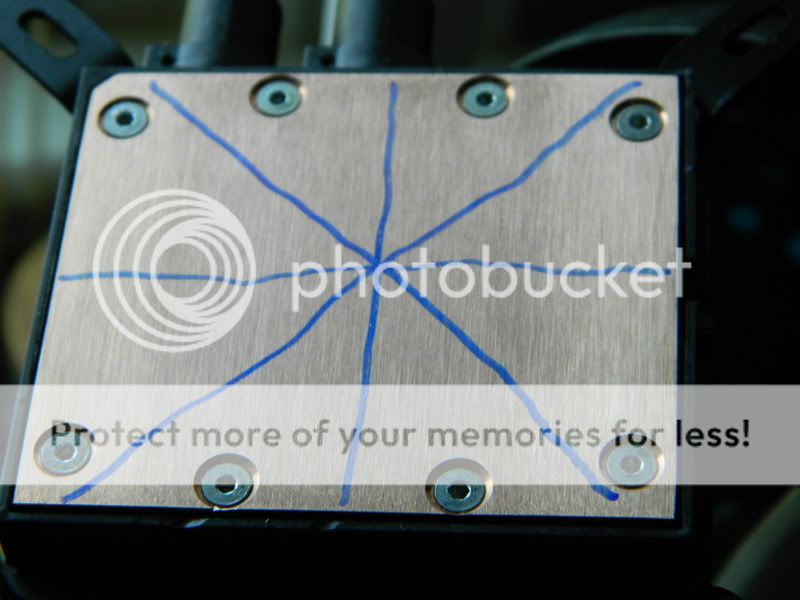

As for motion - 90°C rotations, nothing more, nothing less. It is intentionally done this way so that the scratches created from the prior lapping efforts are being cross-cut and removed at the optimal rate across the entirety of the surface. Doing figure eights, 45-degree rotations, etc is actually not uniform and not optimal (that is an educated statement, not just a guess or an opinion). So if you are going to put in all the time and effort anyways, may as well maximize what you get from the effort.

90-degree rotation every 10-15 swipes (push away, pull back = one swipe).

That said - there is a time and a place for doing 45° rotations and figure-eights and that is when you are starting out on a new grit and you want to see how uniformly you managed to lap the surface with the prior grit (check to see if you off-balanced the specimen by applying too much downpressure on one side or the other).

In that case a very brief figure-8 (maybe 2 or 3 loops) or a few 45-degree swipes followed by visual inspection of the uniformity of your newly minted scratch pattern will tell you if you left the previous grit too soon and perhaps you should go back to it again. If you leave a grit to soon, trying to rush through and save time, the problem is you find yourself spending forever and day on the next grit trying to remove scratches that should have been removed with the prior grit.

For example, maybe you created a particularly deep scratch from a nodule on the 220 grit. Normally you'd remove it with the 400 grit before moving on to the 800 grit, but if you rush through the 400 grit then when you get to the 800 grit paper you will spend a lot of time removing the same 220 grit-induced scratch because the 800 grit paper makes for much slower removal rates.

If you read through my

NH-D14 vs H100 thread in cases and cooling subforum, or the

lapped my 3770k thread in this subforum you'll get a good idea of what to do.

That said, while I may have been trained on doing this stuff I can also tell you that doing it the other ways is not going to necessarily be a bad thing either. Worst case is you use oil and you lapping efforts are undermined by scratches that never go away, or you do figure-8 type polishing and you probably spend just a bit more time lapping versus the time you would spend if you did 90-degree rotations.

In other words, there is no wrong way, but there an optimal way when it comes to how much time it is going to take you to achieve a given result.

The one thing you don't want to do is you do not want to use a buffing compound at the very end just to get a mirror-like polish. The buffing compound will actually create a chemical oxide on the surface that is thicker/deeper than that created by the native oxide, and the thicker chemical oxide will have inferior thermal conductivity (running counter to the very reason you are lapping your CPU in the first place).

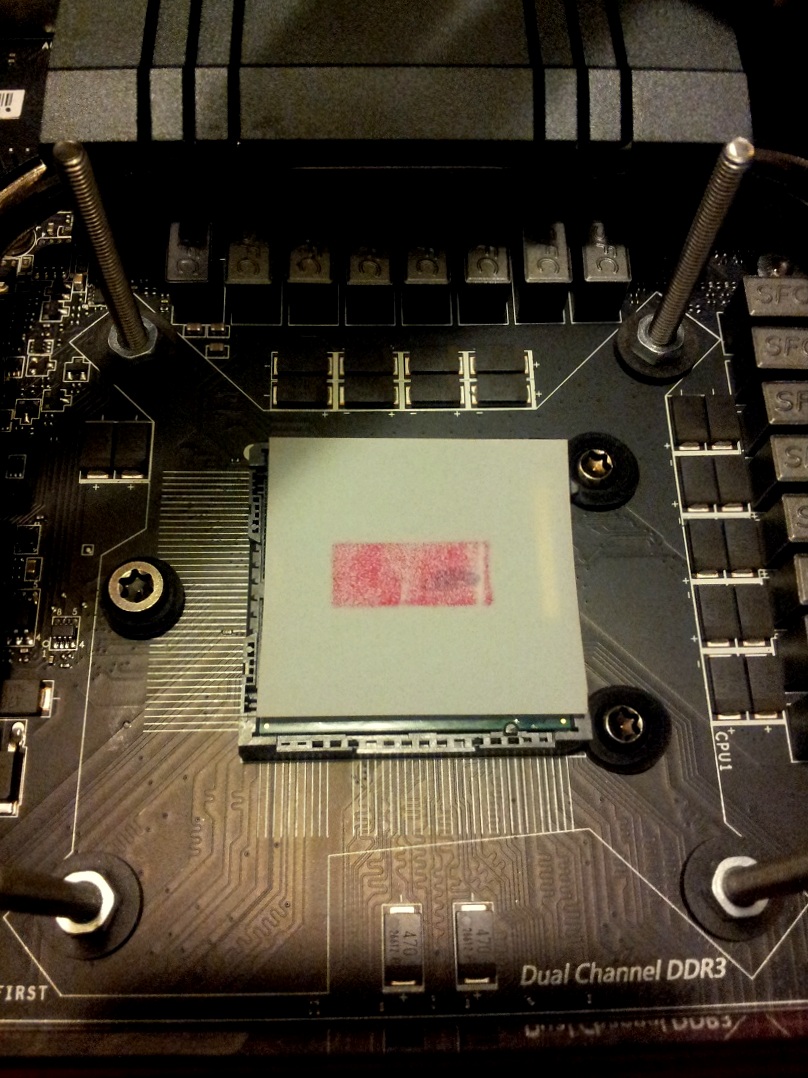

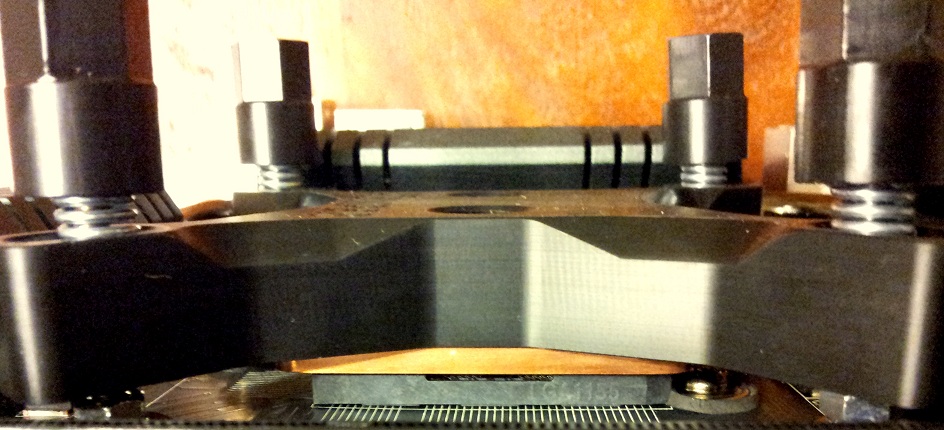

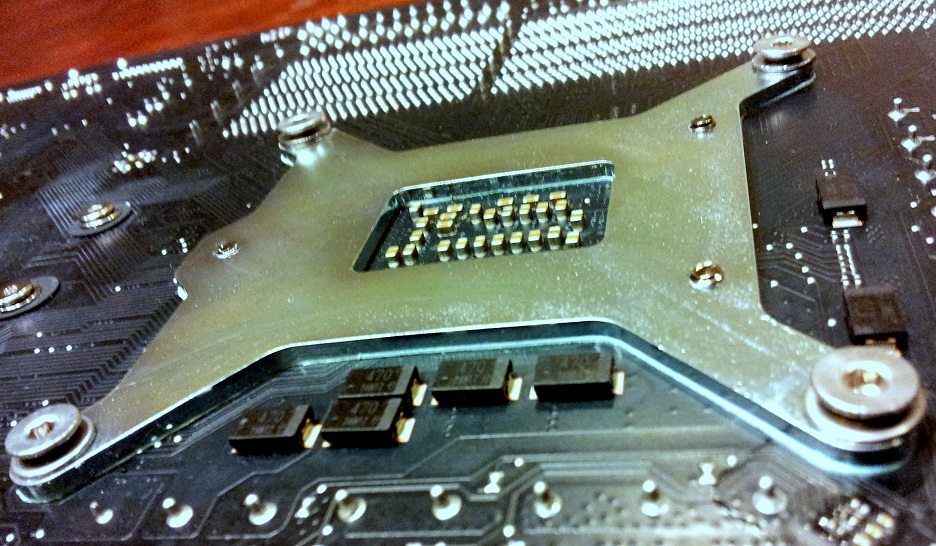

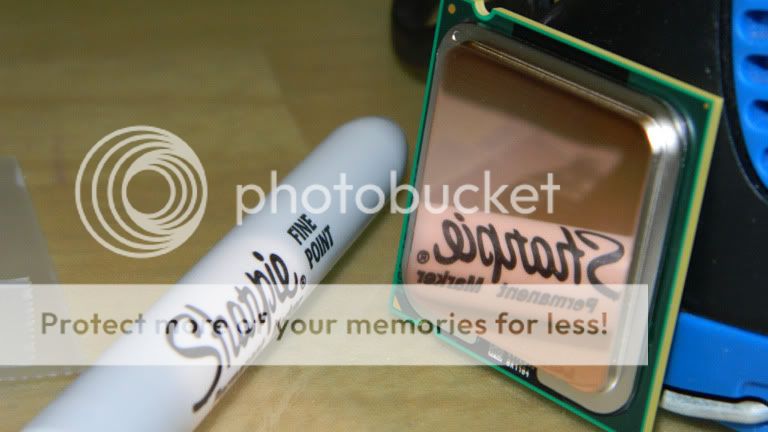

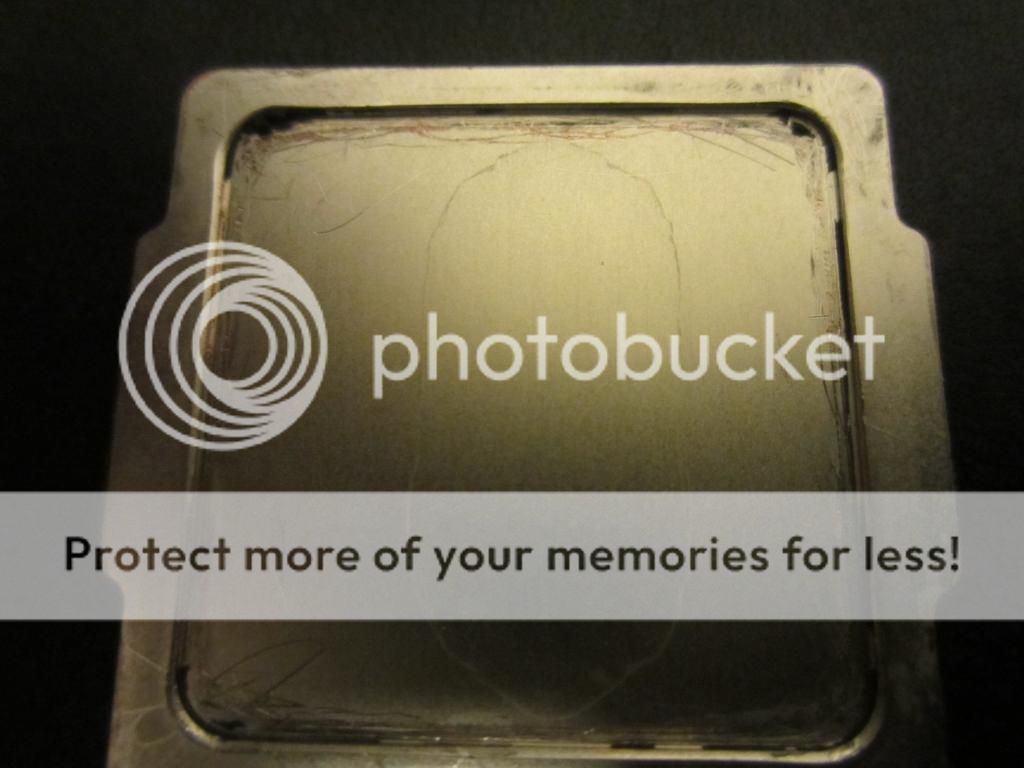

If you want a nice mirror-like polish then you should use 3000 grit (a dry grit available in a pad format at auto-parts stores) as your final polish step. (the following images are all from various CPUs and HSFs that I lapped to 3000grit)