As alluded to in the OP, I did my best to attempt to salvage the CPU TIM that Intel uses on their Ivy Bridge cpus so that I could test it as a plain-ole TIM on my 2600K and compare it with other TIMs.

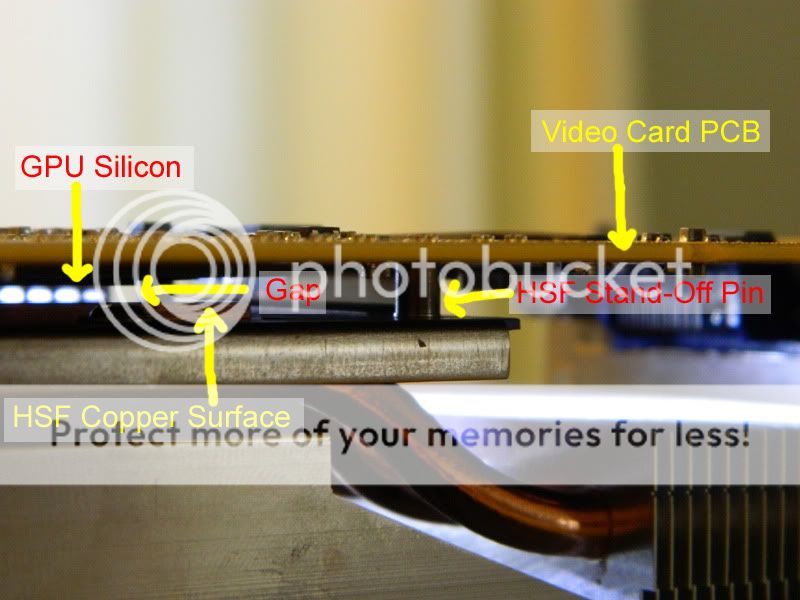

After the decidedly unfavorable results from my re-sandwiching attempt with the original Intel CPU TIM (

detailed in this post) I took the lid back off the CPU:

^ lots of CPU TIM to scrape off and recover for this test.

^ all cleaned up, but what does the CPU TIM look like once it has been removed?

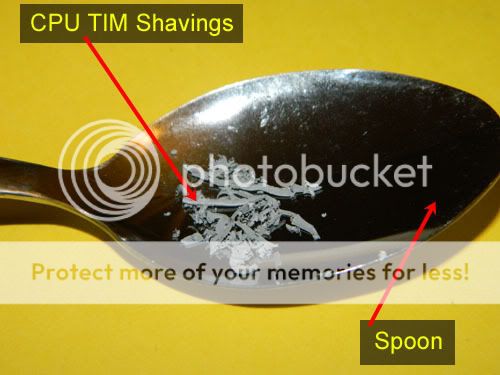

Answer: it looks a lot like pile of metal shavings in a spoon

(fascinating though that the TIM shavings realize it is they who bend rather than the spoon)

Seriously though the shavings of CPU TIM are really indicating to you just how stiff and non-pliable the TIM itself really is. It is hard, like a thick sheet of plastic that has been cut into shavings with a razor blade. Nothing at all like the malleability of traditional TIMs (including that used on Intel's stock HSF's).

There was no way I could just plop this pile of shavings on top of my 2600K and expect any kind of results that would be representative of the thermal conductivity properties of the bulk TIM as applied to the 3770k cpu.

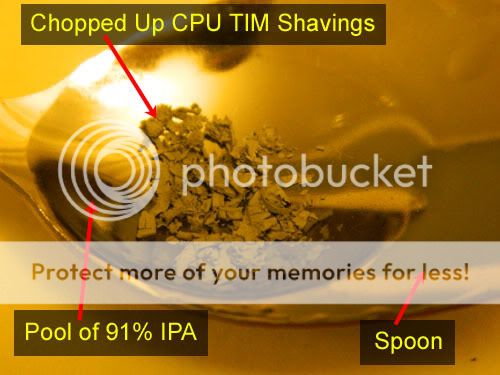

So I decided I would make an attempt to rejuvenate the TIM...and since we use IPA to remove TIM because it does such a wonderful job of dissolving the TIM (after all that is exactly how I cleaned up the 3770k silicon die and IHS as shown in the photo above) I figured I'd dissolve the TIM shavings in some IPA and then let the IPA evaporate, leaving behind a puddle of pliable gooey CPU TIM.

Ah, if only. You know what they say about theory versus practice? In theory there is no difference between theory and practice, but in practice there is!

The shavings weren't interested in dissolving in the IPA by any means. I even heated up the IPA with a simple water bath (double-boiler style) and chopped up the shavings with the razor blade to get them as small as possible...but there was not "mushing" them, way too hard and stiff. Here's the best I could do to recover the CPU TIM as re-appliable TIM...this is after soaking in hot 91% IPA for nearly 2 hrs:

I left the spoon sit out long enough for the bulk of the IPA to evaporate, trying to give the shavings as much of a chance as possible of absorbing the IPA in hopes of the CPU TIM becoming malleable from the

polymer swelling effect alone.

What I had left over was pretty much what I started with, albeit the bits of CPU TIM were now much smaller because of all the chopping I had done in the effort to get them to dissolve in IPA.

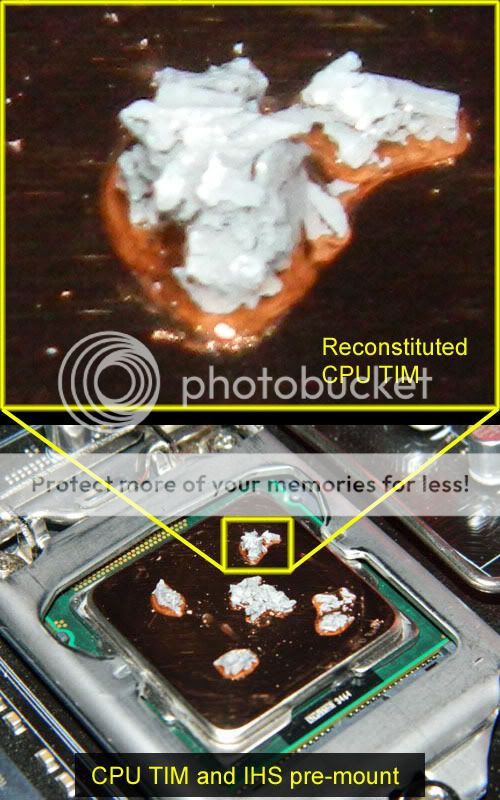

I elected to make 5 piles of the CPU TIM on my 2600k IHS, versus just one big pile in the middle of the IHS, because I wasn't overly optimistic that the TIM was going to spread out to cover the whole IHS.

When I was done with my tests I removed the H100 and checked to confirm how well, or not as it were, the CPU TIM had spread out under the pressure of the H100 and the thermal cycling of the LinX testing:

^ yeah, not good at all. What you can't see in this picture is that the 5 spots of CPU TIM were like pancakes, probably 0.5-1mm thick (not thin by any stretch of the imagination), acting as pedestals keeping the H100 hoisted above the IHS so thermal contact was truly not happening.

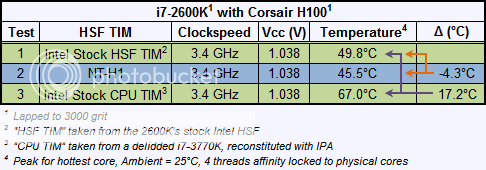

And the results? About as disastrous as you would expect them to be given how poorly the mount was in this effort:

Ouch

At the stock clock of 3.4GHz for my 2600k, the CPU TIM test was pushing temperatures up by a solid +15-20°C over that observed with standard TIMs.

Now obviously this result is not indicative of the actual performance of the CPU TIM that Intel is putting on their Ivy Bridge CPUs, these results are botched because of the inability of the TIM to be recovered and reapplied to subsequent surfaces like my 2600k's IHS.

All well, I guess for now the mystery of "how good, or crappy, is the stock Intel CPU TIM?" will have to go unanswered.