- Dec 8, 2010

- 11,900

- 74

- 91

My 3770K has always been a bit of a hot head, especially now that I've resorted to using Intel's stock cooler. What's more, its warranty just expired... So there's only one way forward: crack it open and put some metal on!

Equipped with Coollaboratory Liquid Pro and a vice, I was eager to continue. Problem was, the vice was rusted, made worse by the fact that my dad crafted it way back when in school. For now, I had to leave the CPU sweating in its socket.

To melt off the rust, I soaked the vice in a vinegar salt solution for about 40 hours. The bulk of the rust dissolved, but there was still some rust visible after scrubbing with steel wool. At least the old industrial green paint came off easy. One part of the tool just removed from the vinegar bath:

Now painted black (with paint compatible with rusted surfaces):

What a beauty. Now, to the matter at hand.

The CPU, its old paste wiped off with IPA and secured between the jaws of the vice (which were covered with sticky tape):

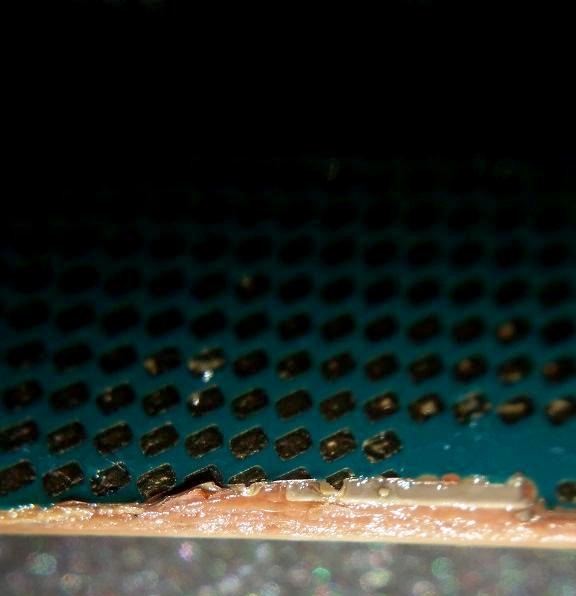

The head came off easily when adding pressure constantly and slowly. The stock paste was very tough and in some parts dried, but IPA did its trick. Most of the glue I scraped off with an IKEA family card.

A droplet of liquid metal on the die (probably slightly too much, but no matter). Spreading it was easy with the supplied Q-tip.

First the CPU back in the socket, then the lid back on (about 5 mm offset towards the base of the locking mechanism).

My "test bench" was assembled on nothing more than the motherboard's cardboard box. In a well ventilated case, cooling would be much better. Ambient temperature was about 24°C or 75 F during testing.

The essential specs -

CPU: i7-3770K, Vcore offset -0.045 V

Cooler: Intel stock with Arctic MX-4

Motherboard: Asus P8Z77-V

Fan RPM during idle was 1000, during load it was 2000. These are the stock fan's minimum and maximum, respectively. At minimum RPM, the cooler is whisper quiet, while at maximum it's not terribly noisy but annoying if continuous.

Idle temperature was measured after 10 minutes of waiting, and the reported figure is the average of minimum core temperatures. Load was achieved with 10 minutes of Prime95 SmallFFT, on two settings: stock 3.7GHz turbo, and 3.9GHz (stock single core turbo forced an all four cores). The reported figure is the average of maximum core temperatures.

This is the part you came here to read, am I right?

More than 13 °C improvement at 3.9GHz! A clock speed that previously was too hot for 24/7 use, was now fine. I didn't quite expect such results with only the stock cooler - I have to admit, I'm very pleased. A massive difference with just a 10 euro investment and a bit of manual work.

(Original screen caps combined from HWInfo64.)

Thanks for reading!

Equipped with Coollaboratory Liquid Pro and a vice, I was eager to continue. Problem was, the vice was rusted, made worse by the fact that my dad crafted it way back when in school. For now, I had to leave the CPU sweating in its socket.

1. Refurbishing the vice

To melt off the rust, I soaked the vice in a vinegar salt solution for about 40 hours. The bulk of the rust dissolved, but there was still some rust visible after scrubbing with steel wool. At least the old industrial green paint came off easy. One part of the tool just removed from the vinegar bath:

Now painted black (with paint compatible with rusted surfaces):

What a beauty. Now, to the matter at hand.

2. Delidding

The CPU, its old paste wiped off with IPA and secured between the jaws of the vice (which were covered with sticky tape):

The head came off easily when adding pressure constantly and slowly. The stock paste was very tough and in some parts dried, but IPA did its trick. Most of the glue I scraped off with an IKEA family card.

3. Applying Liquid Pro

A droplet of liquid metal on the die (probably slightly too much, but no matter). Spreading it was easy with the supplied Q-tip.

First the CPU back in the socket, then the lid back on (about 5 mm offset towards the base of the locking mechanism).

4. Test bed and method

My "test bench" was assembled on nothing more than the motherboard's cardboard box. In a well ventilated case, cooling would be much better. Ambient temperature was about 24°C or 75 F during testing.

The essential specs -

CPU: i7-3770K, Vcore offset -0.045 V

Cooler: Intel stock with Arctic MX-4

Motherboard: Asus P8Z77-V

Fan RPM during idle was 1000, during load it was 2000. These are the stock fan's minimum and maximum, respectively. At minimum RPM, the cooler is whisper quiet, while at maximum it's not terribly noisy but annoying if continuous.

Idle temperature was measured after 10 minutes of waiting, and the reported figure is the average of minimum core temperatures. Load was achieved with 10 minutes of Prime95 SmallFFT, on two settings: stock 3.7GHz turbo, and 3.9GHz (stock single core turbo forced an all four cores). The reported figure is the average of maximum core temperatures.

5. Temperatures

This is the part you came here to read, am I right?

Code:

Setting ... °C before ... °C after delid

Idle ...... 40.25 ....... 36.5

3.7 GHz ... 81.5 ........ 71.5

3.9 GHz ... 93.75 ....... 80.5More than 13 °C improvement at 3.9GHz! A clock speed that previously was too hot for 24/7 use, was now fine. I didn't quite expect such results with only the stock cooler - I have to admit, I'm very pleased. A massive difference with just a 10 euro investment and a bit of manual work.

(Original screen caps combined from HWInfo64.)

Thanks for reading!

Last edited: